They were two smaller ones from a set I have. They were just wide enough to clear the MT2 taper but still push on the drive flange of the arbor and drive collar. Btw, I didn’t pry with them, merely put them tip to tip (overlapping) and as I pushed them together the tapers created a wedging action. Once they were tight by hand I took two hammers and simultaneously hit them together. After two light blows the Arbor popped out.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Atlas MFC - loose and jammed arbor?

- Thread starter brandon428

- Start date

- Joined

- Dec 25, 2011

- Messages

- 10,511

Brandon,How would I even pull the shaft? Figured I’d have to get the arbor out before I’d be able to do that.

You can actually pull the spindle out with the arbor and arbor driver still in place.

Remove enough of the countershaft to get the spindle belt free of the countershaft cone pulley.

Remove the front arbor support.

Remove the draw bar.

Remove the nut that sets the bearing preload from the rear of the spindle.

Remove the gear and spacer from the rear of the spindle.

Loosen the set screw in the bull gear.

Rotate the spindle to line up the Woodruff key in the bull gear with the slot in the inner front spindle bearing dust cover.

Remove whatever else I have forgotten.

Figure out how to grab it and pull away.

However, I don't know that it will be any easier to separate spindle and arbor with both out of the head.

- Joined

- Nov 15, 2020

- Messages

- 139

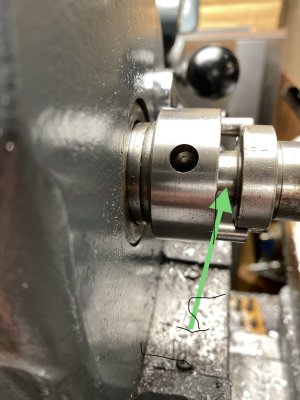

I assume you put the forks here in between the pins?They were two smaller ones from a set I have. They were just wide enough to clear the MT2 taper but still push on the drive flange of the arbor and drive collar. Btw, I didn’t pry with them, merely put them tip to tip (overlapping) and as I pushed them together the tapers created a wedging action. Once they were tight by hand I took two hammers and simultaneously hit them together. After two light blows the Arbor popped out.

Attachments

- Joined

- Nov 2, 2013

- Messages

- 962

The pickle forks idea sounds like a good one. Maybe the tools used to remove automotive tie rod ends would work. I think some of the big chain auto part stores rent/loan them too. I don't know if they'd fit going between the shaft & pins but maybe inline with the pins?

Yes, with one pickle fork coming in from each side.I assume you put the forks here in between the pins?

- Joined

- Nov 15, 2020

- Messages

- 139

I measured the morse at the point I could get at with my calipers which is 0.700". The smallest size pickle forks I can find are 11/16", so might need to shave. On the other hand, the fork widths are 1/4" each, and the distance between the pins is 1.110, so I'm really surprised you didn't need to shave the outside to get these to fit...

- Joined

- Nov 15, 2020

- Messages

- 139

Ah, got it, oriented that way you don't have to worry about the pins.

Incidentally, it looks like #6 Jacob's Wedges have a .717 inner diameter, so I suppose I could try those as well. Maybe using a vise like in that video or a C-clamp instead of a hammer.

Incidentally, it looks like #6 Jacob's Wedges have a .717 inner diameter, so I suppose I could try those as well. Maybe using a vise like in that video or a C-clamp instead of a hammer.

- Joined

- Nov 15, 2020

- Messages

- 139

Ok, tried the #6 Jacob's wedges and they get stuck on the pins before they clamp. Pickle forks must have more depth. I may shave off the outside to see if I can get them to fit within the pins.

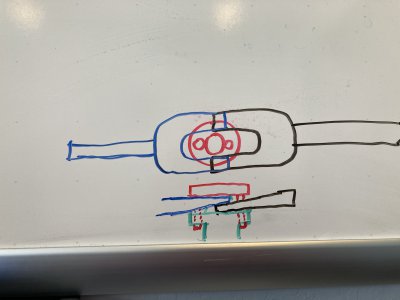

I also found out what was causing my play -- the middle gear appears to be slightly unaligned from the pulley, which is causing some slop in the rear bearing. [picture attached]. I'm guessing my hammering must have popped that loose, but I can't get other parts of the spindle to move independently, so I think I need to take apart the spindle to adjust it.

Does anyone have a picture of the nut that sets the bearing preload at the rear of the spindle that's been mentioned a few times. I can't seem to find that part on my spindle.

I also found out what was causing my play -- the middle gear appears to be slightly unaligned from the pulley, which is causing some slop in the rear bearing. [picture attached]. I'm guessing my hammering must have popped that loose, but I can't get other parts of the spindle to move independently, so I think I need to take apart the spindle to adjust it.

Does anyone have a picture of the nut that sets the bearing preload at the rear of the spindle that's been mentioned a few times. I can't seem to find that part on my spindle.