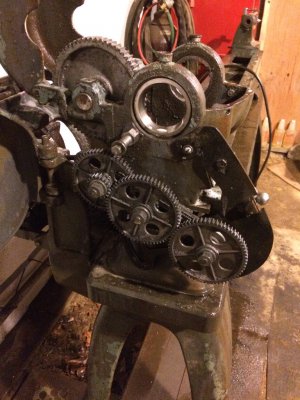

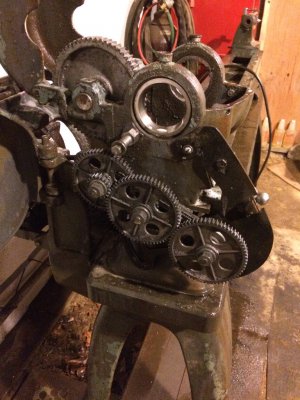

Some updates on the overall project. I've splayed and scrubbed what I can with a toothbrush so far. I really need the hose to blow off some of the packed in stuff. Would anyone recommend against soaking the motor down. I plan to blow it out with air and let it sit for about a week before I try to run it again. That's if I decide to not pull it off and take it apart.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk