Thank you for the information - I greatly appreciate it. Currently there are shims under 2 of the four bolts, so I'll mess around with some shim stock and try to get it dialed in better. The bigger issue seems to come from putting pressure from the tailstock into the headstock (like when I'm trying to secure a piece of wood between the dead center on the headstock and live center on tailstock). I can really slow down the speed if I crank on it to hard. Might just be me getting used to the thing (coming from a 8x12 pen making lathe).Bigolac,

It was most probably made in 1936 and was sold as a wood lathe under the catalog number of 99PM2026. What's there is the same as on the Craftsman 101.07360. What the actual model number is would require finding the owners & parts manual that was sold with it.

However, to get back to the bearings, if the left bearing is getting hot after running a few minutes, it is too tight.

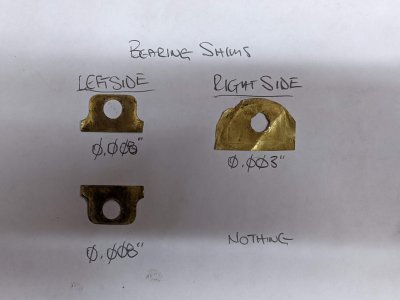

The Atlas babbit bearing lathes that Sears sold and Atlas made left the factory with two 0.010" shim packs, one under each gearing cap bolts. Each shim pack was made up of five 0.0002" shims laminated together. So you need to get a roll of 0.002" shim stock and cut out a few shims. Stack them and clamp between two pieces of wood. drill the 3/8" bolt holes. Add one shim under each bolt and torque them down to about 20 to 25 lb-ft. If too loose, remove one shim and try it again. If still too tight, and one more shim and check again. After several minutes run-time. the bearing should get a little warm but not hot.

There is a PDF of the 1936 Power Tools catalog in Downloads. Full access to Downloads requires Donor status (any level). Unfortunately, we do not appear to have a copy of the nearest to correct parts list. All that we have are about one revision too new. And all have the back gears. And the only illustrated parts list that we have is several revisions too new, being the one on the 101.07383.

Next steps will be to make a mount for the motor - the one I got with this lathe is a Craftsman 1/2hp that weighs about 40 pounds with plenty of torque.

Hard to believe how true this lines up after 80 some odd years of use. I think with a little care and attention, it will continue to give years of use and joy.

Last edited by a moderator: