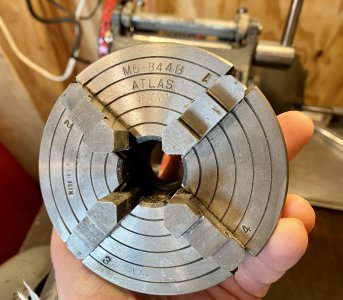

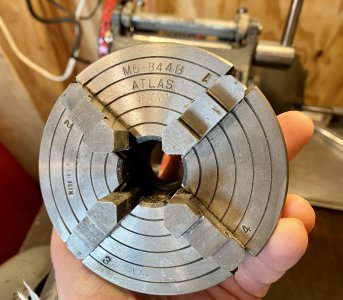

This little 4 jaw chuck came with my Atlas 618 Lathe that I just got up & running recently and I never really looked at it until I needed a 4 jaw last night. It was just in a box. everything seems good and it works well but a few of the jaws are stiff, presumably from dried up grease. I've never disassembled one of these so any advice, tips or tricks are appreciated as far as order of jaw removal, etc. Here are some pictures to show it's as-found and current condition. -John