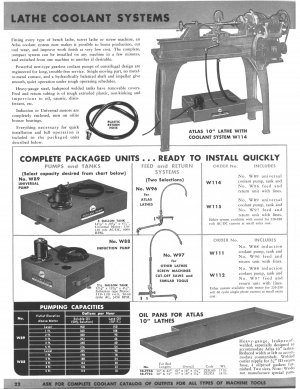

I've been wanting to break a chip tray for my atlas 10" pretty much since I got it. Now I'm tired of cleaning the oil off the wood block its mounted to and would like a better way to "contain" most of the chips. I had thought of building a full length tray that goes under the bed feet but I'm not sure if it's exactly necessary. I know I'll definitely be going under the headstock foot as the bearings leak oil as fast as I can put it in. So I. That right it's either shim the tailstock side or make the chip tray go all the way. I'm just looking for ideas on dimensions. On the backside I wanted to extend it 6" past the feet as I try to get my tooling to throw the chips away from me if possible. I also though about going 4-5" past the feet on the operator side so I'd have a place to lay some tooling as I don't have shelving around the lathe at the moment. More or less if you could post pictures that would help. I'm unsure what gauge metal to use or how high I should make the lips. I thought about 3/4-1" as I'd like to set this up for flood coolant at some point. As cutting oil does get expensive and I sure do use it!

Also it is a 54" bed model and I believe I can get sheet metal in sheets of 4'x8' if I remember correctly.

Regards-Carlo

Also it is a 54" bed model and I believe I can get sheet metal in sheets of 4'x8' if I remember correctly.

Regards-Carlo