Don't just quietly wait, send an email once in a while. If things do fall apart, the credit card company will ask if you have maintained contact trying to resolve this. I'll bet it works out but, if it doesn't you have covered yourself!Probably, but given the previous responses, I'm comfortable just waiting for now.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone have experience with Pe-We tools?

- Thread starter acruxksa

- Start date

- Joined

- Feb 5, 2020

- Messages

- 117

It's all good and yes, my CC company will certainly cover me if there's ever an issue.Don't just quietly wait, send an email once in a while. If things do fall apart, the credit card company will ask if you have maintained contact trying to resolve this. I'll bet it works out but, if it doesn't you have covered yourself!

This was probably more an issue in my mind than in reality. Yes I would have liked better comms, yes I am absolutely certain no pertanent emails went to my spam folder. But equally, the perceived delay was for a valid reason (saving me some money on shipping), just not a reason I was worried about

- Joined

- Feb 5, 2020

- Messages

- 117

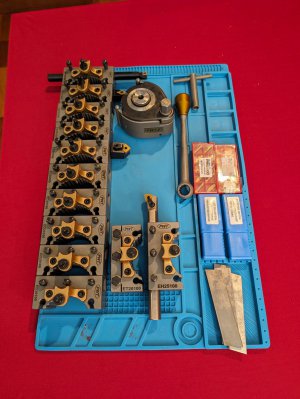

OK, Two separate shipments to keep costs down and a minor misunderstanding on the carbide cutoff blade situation but everything is now here.  When he asked me if I wanted to add a carbide insert cutoff blade I said yes, but didn’t understand how I was supposed to pay for it, so I ordered one with a couple extra holders via his website. He included one with a UPS C.O.D payment prior to delivery.

When he asked me if I wanted to add a carbide insert cutoff blade I said yes, but didn’t understand how I was supposed to pay for it, so I ordered one with a couple extra holders via his website. He included one with a UPS C.O.D payment prior to delivery.  . It’s all good, they are similar but not identical, (2 different carbide inserts).

. It’s all good, they are similar but not identical, (2 different carbide inserts).

I did a quick mount and check to make sure all my tooling will work with the mix of ED20100 and ED16100 MultiFix Holders I ordered. Reason being, is that I have some 5/8” tooling from my old lathe and am gradually moving to 3/4” tooling as I replace things. Prior to purchasing, I had used the pdf on Peter’s home page to determine that my lathe was solidly in the ED20100 parameters and slightly high for the ED16100 holders. ie. I have a 40mm crossslide to center of the spindle distance. ED20100 holders have a range from 30mm - 43mm and ED16100 is 25mm - 36mm. The G0709 is also squarely in the middle of the ED25100 range, but I don’t foresee a need for 1” tooling anytime soon.

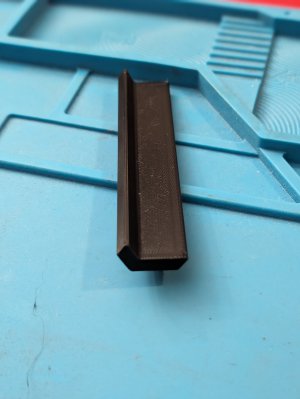

End result, All my tooling is able to properly center out of the box, with the exception of my 3/4” boring bar in the EH25100 holder. This was 6mm low. Current options are to make a spacer with the T-Nut and mounting bolt to raise the Multifix 6mm or make a spacer for the ED25100 to raise the boring bar in the tool holder…….. I whipped up a quick 3d print to see if a spacer will work and it does, so I intend to go that route for now.

Moral of the Story, patience……….I need a lot more of it.

Fortunately, I’m nearly at a point where I can step away from the Jeep repower, just have to disconnect fuel and exhaust and driveline then I’m going to wait until after the holidays to pull the engine and transmission. Should be able to start tackling the Multifix mount in a day or two.

I did a quick mount and check to make sure all my tooling will work with the mix of ED20100 and ED16100 MultiFix Holders I ordered. Reason being, is that I have some 5/8” tooling from my old lathe and am gradually moving to 3/4” tooling as I replace things. Prior to purchasing, I had used the pdf on Peter’s home page to determine that my lathe was solidly in the ED20100 parameters and slightly high for the ED16100 holders. ie. I have a 40mm crossslide to center of the spindle distance. ED20100 holders have a range from 30mm - 43mm and ED16100 is 25mm - 36mm. The G0709 is also squarely in the middle of the ED25100 range, but I don’t foresee a need for 1” tooling anytime soon.

End result, All my tooling is able to properly center out of the box, with the exception of my 3/4” boring bar in the EH25100 holder. This was 6mm low. Current options are to make a spacer with the T-Nut and mounting bolt to raise the Multifix 6mm or make a spacer for the ED25100 to raise the boring bar in the tool holder…….. I whipped up a quick 3d print to see if a spacer will work and it does, so I intend to go that route for now.

Moral of the Story, patience……….I need a lot more of it.

Fortunately, I’m nearly at a point where I can step away from the Jeep repower, just have to disconnect fuel and exhaust and driveline then I’m going to wait until after the holidays to pull the engine and transmission. Should be able to start tackling the Multifix mount in a day or two.

Attachments

-

PXL_20231208_014009493_Original.jpeg287.6 KB · Views: 18

PXL_20231208_014009493_Original.jpeg287.6 KB · Views: 18 -

PXL_20231208_015835606_Original.jpeg188.4 KB · Views: 19

PXL_20231208_015835606_Original.jpeg188.4 KB · Views: 19 -

PXL_20231208_015252453_Original.jpeg224.7 KB · Views: 17

PXL_20231208_015252453_Original.jpeg224.7 KB · Views: 17 -

PXL_20231208_020035202_Original.jpeg181.7 KB · Views: 18

PXL_20231208_020035202_Original.jpeg181.7 KB · Views: 18 -

PXL_20231208_154457243_Original.jpeg158.3 KB · Views: 15

PXL_20231208_154457243_Original.jpeg158.3 KB · Views: 15 -

PXL_20231208_015401952_Original.jpeg247 KB · Views: 16

PXL_20231208_015401952_Original.jpeg247 KB · Views: 16 -

PXL_20231208_163328235.PORTRAIT_Original.jpeg154.7 KB · Views: 16

PXL_20231208_163328235.PORTRAIT_Original.jpeg154.7 KB · Views: 16 -

PXL_20231208_164329725_Original.jpeg351.7 KB · Views: 18

PXL_20231208_164329725_Original.jpeg351.7 KB · Views: 18

Last edited: