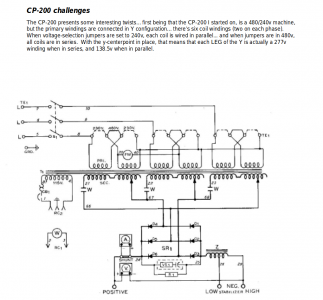

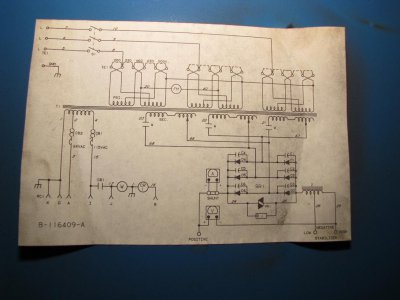

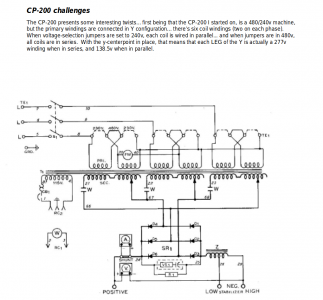

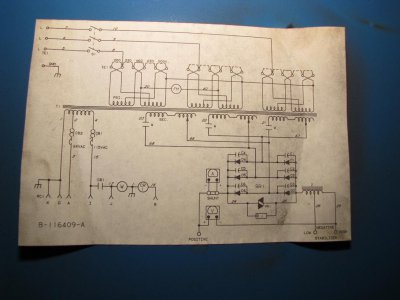

I am still studying it. From the wiring diagram lifted from Practical Machinist, it shows a star-connected primary, and a delta connected secondary where each phase is put through a series capacitor (W). That circuit is the welder, and I am not sure of the value of the capacitors on the way to the rectifier. This is a three-phase welder before messing with it to introduce capacitors into the primary. Also shown is the connections to convert to the Haas-Kamp method.

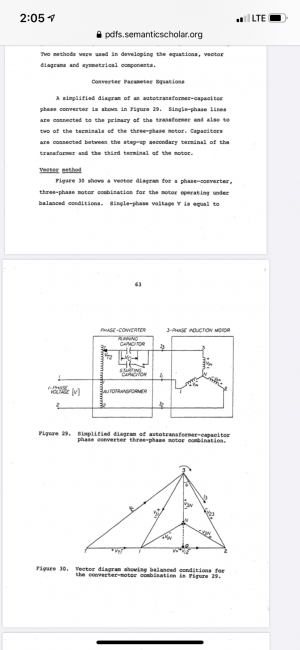

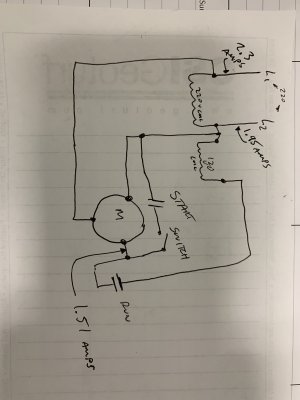

In normal 3-phase, the phases are 120° apart. The Haas-Kamp connection uses two windings on a single phase core, one connected "backwards", to deliver two phases 180° apart. Then, in the style of motor-starting capacitors, a third phase is contrived by using a 90° phase shift from capacitors, except they have to run the full AC current all the time, not just when starting. The vector diagram shows the phase relationships.

It would appear that the sequence is 0°, 90°, 180°, --repeat. It would be a "sort of" three phase, I think, and I hope I do not understand it wrong.

It can deliver energy, and I suppose adding a couple of capacitors, and re-working some primary connections is a fast, and relatively low cost dodge to make a 3-phase welder accept a single phase input.

I can believe that if I was trying it, the switch-on moment would involve a hard swallow, eyes shut, face tucked onto shoulder, arm at full extent to the ON switch, left hand fingers firmly crossed, and silent invocations to Jesus, Mary, Allah, Thor, Buddah and Zeus and any others to please make it go well!

- -