- Joined

- Sep 8, 2019

- Messages

- 4,392

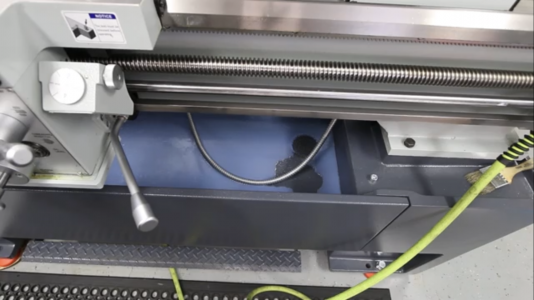

I haven’t started researching it yet, but my new lathe has a flood coolant system.

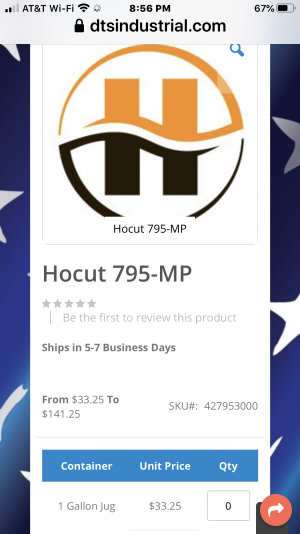

I was just wondering if you guys have any good or bad experiences with any particular brand or type of flood coolant.

I saw one video where the guy was using a refractometer to see if he got the mix just perfect. Hopefully I can skip that because I can’t afford a refractometer at this point.

I was just wondering if you guys have any good or bad experiences with any particular brand or type of flood coolant.

I saw one video where the guy was using a refractometer to see if he got the mix just perfect. Hopefully I can skip that because I can’t afford a refractometer at this point.