-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- GENERAL TYPES OF METALWORKING MACHINES

- ANTIQUE & VINTAGE MACHINERY

- MISC ANTIQUE & VINTAGE MACHINERY

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Antique Hardindge Bench Lathe. How to remove spindle head

- Thread starter medida

- Start date

- Joined

- Apr 23, 2011

Well Dean, I found a bit more info.....

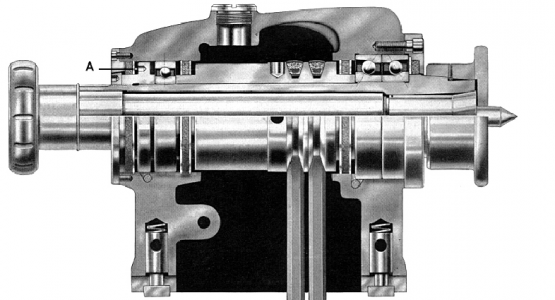

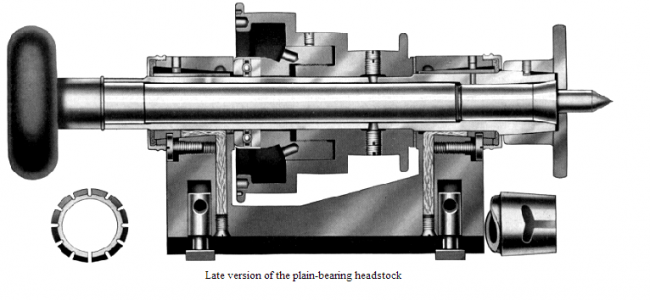

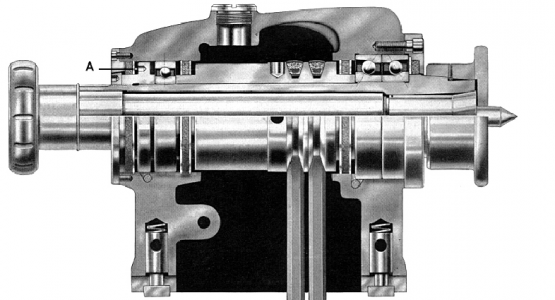

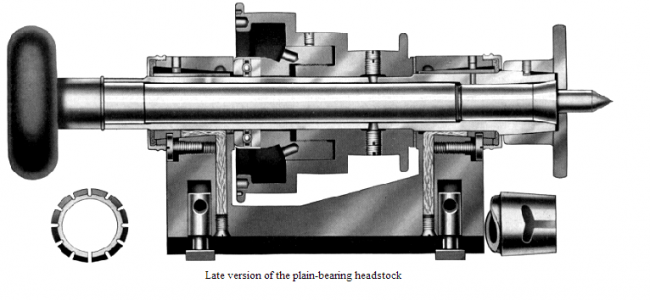

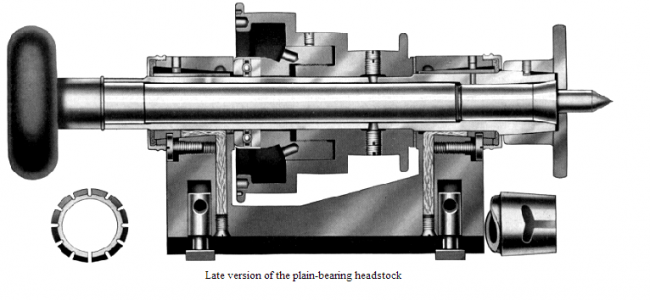

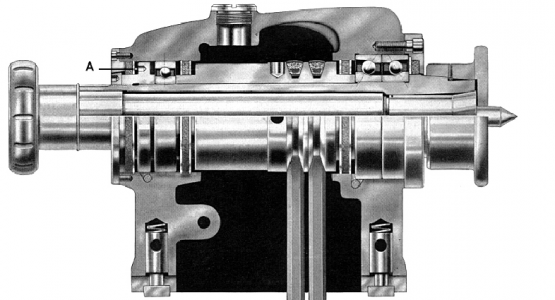

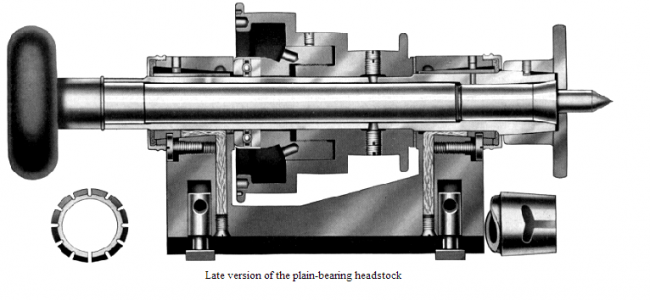

These dont show the method of retaining the t-bolts but at least you get the idea.

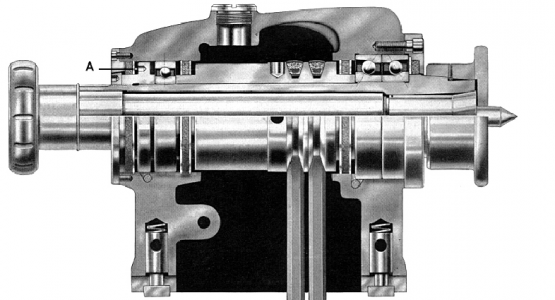

But then I found this!

So it appears that they are held in place by cams. Can you clean down in the holes from the back and see a) a hex head, or b) a screwdriver slot? To turn the cam bolt.

credit to lathes.co.uk for images

Cheers Phil

These dont show the method of retaining the t-bolts but at least you get the idea.

But then I found this!

So it appears that they are held in place by cams. Can you clean down in the holes from the back and see a) a hex head, or b) a screwdriver slot? To turn the cam bolt.

credit to lathes.co.uk for images

Cheers Phil

- Joined

- Apr 23, 2011

I also found this thread http://www.hobby-machinist.com/showthread.php/12703-Can-you-help-me-disassemble-this-headstock but the author doesnt seem to be very active on here. Maybe try and pm him and see if you get a response.

cheers Phil

cheers Phil

PHIL

thanks for the url.

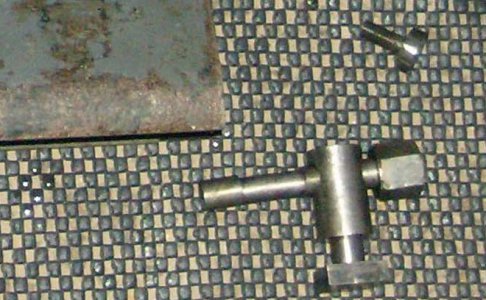

I had seen the UK lathe site and it's cross section. I think you are right, these are broken off cam pins. This would explain the rough surface end and how the two are not recessed the same amount. I also confirmed that there is no holes on the other side

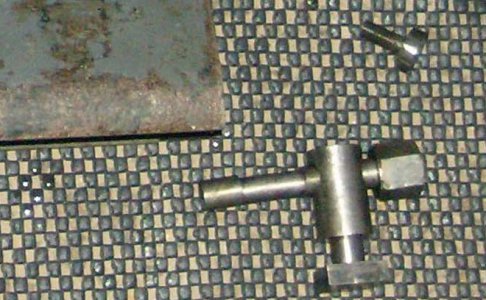

I also found two cam bolts in the parts that I got with the lathe. One looks to be the original and the other was made from a standard 3/8 bolts. I expect the PO had broken them and gotten the other parts to replace...but never got around to it.

Trying to think how to take this apart now

go to this url and you will see the pics

http://s1280.photobucket.com/user/Medida/library/Hardinge Lathe?sort=2&page=1

thanks for the url.

I had seen the UK lathe site and it's cross section. I think you are right, these are broken off cam pins. This would explain the rough surface end and how the two are not recessed the same amount. I also confirmed that there is no holes on the other side

I also found two cam bolts in the parts that I got with the lathe. One looks to be the original and the other was made from a standard 3/8 bolts. I expect the PO had broken them and gotten the other parts to replace...but never got around to it.

Trying to think how to take this apart now

go to this url and you will see the pics

http://s1280.photobucket.com/user/Medida/library/Hardinge Lathe?sort=2&page=1

- Joined

- Apr 23, 2011

Try putting a file to the "original" looking cam bolt. That might give you an idea about its "drill-a-bility"

i think drilling is going to be your best option here. It will be difficult to stop the drill from wandering down in that deep hole. Maybe look at making a bush to locate the bit. I would start with about 1/8th and step up in small increments. Maybe try an ezi-out or if you get closer to full size you may need to use a small flat tool to peel the remaining cam out. dremel maybe, but thats a long shank to go in there.... Otherwise if that is not do-able, and if you think you could accurately locate on the front side, (where you looked for through holes) maybe drill through from there and get a suitable pin punch in to knock them back out. In the meantime lay the lathe over and fill the holes with some penetrating oil while you consider your options. Good luck

Cheers Phil

i think drilling is going to be your best option here. It will be difficult to stop the drill from wandering down in that deep hole. Maybe look at making a bush to locate the bit. I would start with about 1/8th and step up in small increments. Maybe try an ezi-out or if you get closer to full size you may need to use a small flat tool to peel the remaining cam out. dremel maybe, but thats a long shank to go in there.... Otherwise if that is not do-able, and if you think you could accurately locate on the front side, (where you looked for through holes) maybe drill through from there and get a suitable pin punch in to knock them back out. In the meantime lay the lathe over and fill the holes with some penetrating oil while you consider your options. Good luck

Cheers Phil

Well Dean, I found a bit more info.....

View attachment 70265 View attachment 70266

These dont show the method of retaining the t-bolts but at least you get the idea.

But then I found this!

View attachment 70267

So it appears that they are held in place by cams. Can you clean down in the holes from the back and see a) a hex head, or b) a screwdriver slot? To turn the cam bolt.

credit to lathes.co.uk for images

Cheers Phil

Thanks for the illustrations. I am not a machine re-builder but my Dad was, part of of his job, a maintenance-man.

Looking at the pin lying next to your ruler makes me wonder if this system of tightening/loosening, is something like an old lathe I have lying by me, If one looks in the horizontal holes in the headstock casting you will be able to see the transverse thro' hole in the pin, & the bottom of this transverse hole slightly up from the bottom face of horizontal holes.

take a portion of bar set up in a four jaw chuck & turn a slight length "off centre" thus making a cam shape, On the outer end of the bar cross drill for a tommy bar feed bar in, till cam portion is in transverse hole in the vertical tee bolt. Lightly push down or tap tommy bar in appropriate direction & this should take the pressure of your tee bolt section & allow head or tailstock to slide free

Guess your Hardinge system was not far away from my removal method, or my old lathes locking system either, Luckily I have the "Cam Bars" that came with the lathe

Core- Oil