I have an old 13" South Bend turret lathe that I've been working on rebuilding & I'm trying to figure out how I want to wire the motor up.

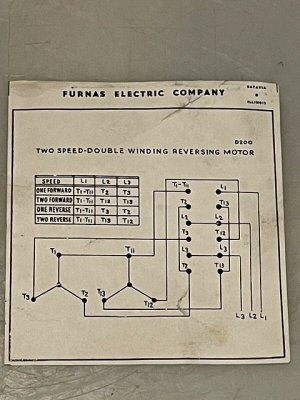

The motor is a 3PH 240V 2-speed dual-winding motor & I would like to make use of both speeds in fwd. & rev.

When I first looked inside the original power disconnect enclosure and seen THIS MESS, I knew that I was going to totally rewire the lathe.

Originally, I was thinking of running it off of a VFD!

However, from what I've read on-line it's recommended to run this type of motor on just the high-speed windings.

During my searches I found a couple of VFD'S that have two separate sets of motor parameters, so it would be possible to set one up for each set of windings. However, I've also read that it generally not recommended to have a switch or contactor/starter placed in-between the VFD & motor?

I do have a 5HP DIY RPC so I could always run the high-speed off of a VFD & then run the low-speed from the RPC.

But somehow that sounds like an accident waiting to happen.

Probably the best solution would be to just wire the lathe up to several starters with the coils controlled by pushbuttons or switches.

This is where I'm looking for some more information on the AB line of starters, mainly the reversing starters with the mechanical interlock set-up.

I have several AB-509 starters & matching relays on hand that I picked up from a local on-line auction so naturally I would like to use AB starters since I'll have extra parts if needed.

Looking on e-bay I see a bunch of the AB-505 style reversing starters & only a few of the two-speed AB-520 style starters.

The 520's I've seen seem to be grossly over-priced

Is there anything really different in the 505 reversing starters & the 520 two-speed starters other than the extra relay?

Doug

The motor is a 3PH 240V 2-speed dual-winding motor & I would like to make use of both speeds in fwd. & rev.

When I first looked inside the original power disconnect enclosure and seen THIS MESS, I knew that I was going to totally rewire the lathe.

Originally, I was thinking of running it off of a VFD!

However, from what I've read on-line it's recommended to run this type of motor on just the high-speed windings.

During my searches I found a couple of VFD'S that have two separate sets of motor parameters, so it would be possible to set one up for each set of windings. However, I've also read that it generally not recommended to have a switch or contactor/starter placed in-between the VFD & motor?

I do have a 5HP DIY RPC so I could always run the high-speed off of a VFD & then run the low-speed from the RPC.

But somehow that sounds like an accident waiting to happen.

Probably the best solution would be to just wire the lathe up to several starters with the coils controlled by pushbuttons or switches.

This is where I'm looking for some more information on the AB line of starters, mainly the reversing starters with the mechanical interlock set-up.

I have several AB-509 starters & matching relays on hand that I picked up from a local on-line auction so naturally I would like to use AB starters since I'll have extra parts if needed.

Looking on e-bay I see a bunch of the AB-505 style reversing starters & only a few of the two-speed AB-520 style starters.

The 520's I've seen seem to be grossly over-priced

Is there anything really different in the 505 reversing starters & the 520 two-speed starters other than the extra relay?

Doug