-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advice on Monarch 10EE and Bridgeport Series 1 acquisition

- Thread starter Macca

- Start date

- Joined

- Jun 12, 2014

- Messages

- 4,810

Some of the 10EE models can be run off of single phase, since the whole DC drive is run off a transformer. But varies by model. It is all about condition and if it runs. Many parts are not replaceable, or may be very expensive, so if you need to be confident with your skills to determine the function of the machine and the repairs. With a VFD system, if you use a smaller motor say a 5Hp you would want to retain the back gear and that is a complex build, others have used an oversized motor 7.5-10 Hp which requires a larger VFD/costs.

- Joined

- Feb 25, 2021

- Messages

- 3,129

1) Go get them. Free, with tooling? If you don't get them and you do get involved in this with other machines, you'll soon realize what you passed up. Seriously, run, do not walk ...

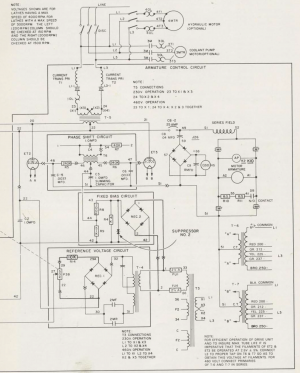

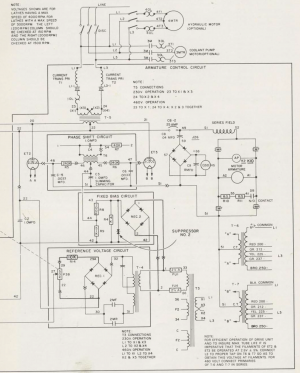

2) The 10EE can be a challenge to fix up the electronics, especially in the MG section (from someone with degrees in electrical engineering). The schematic @mksj shows is from a 60's era, matches my 1964, not applicable to a motor generator machine. Switching it out with a 7.5/10 HP 3 phase motor, and an oversized VFD so it can run on single phase, is likely the best option if there are any challenges with that part of the drive. Don't mess with it if it works. That is probably a $2-3k endeavor. Sometimes the MG machines just need new brushes and a little TLC so it is possible to make it work as is. Regardless, top of the line equipment, you won't get a machine in the same ballpark for twice that.

A Motor-generator 10EE requires 3 phase to run. Since 3 phase is not readily available in residential power, typically a rotary phase converter is used to power these. In short a rotary phase converter (RPC) uses a 3 phase motor as self-contained 3 phase generator. It requires a 3 phase motor to be used as an "idler", typically of twice the horse power that you're trying to run, and some peripheral electronics (switches, contactors and capacitors). The main advantage of an RPC is it can power more than one machine, although possibly not at the same time. This would allow you to run the Bridgeport and the Monarch from the same RPC.

A variable frequency drive (VFD) is a motor sophisticated piece of electronics that includes a microcontroller/computer, and generates 3 phase power through a frequency range. An appropriate VFD can generate that 3 phase power using residential single phase power input. Normally 3 phase motors turn at a speed dictated by the frequency of the power line (60Hz in the U.S.) and by their internal construction. So the motors turn at one speed. A VFD allows a 3 phase motor to be run at a speed range from about 1/3 the speed to 2x the speed. That range depends on the motor, and may be greater. The VFD senses what is going on with the motor, and has to be wired directly to the motor with some controls attached to the VFD, so a VFD generally only works with one motor. You'd need a VFD for each piece of equipment. But it gives you some improved options on selecting speed.

2) The 10EE can be a challenge to fix up the electronics, especially in the MG section (from someone with degrees in electrical engineering). The schematic @mksj shows is from a 60's era, matches my 1964, not applicable to a motor generator machine. Switching it out with a 7.5/10 HP 3 phase motor, and an oversized VFD so it can run on single phase, is likely the best option if there are any challenges with that part of the drive. Don't mess with it if it works. That is probably a $2-3k endeavor. Sometimes the MG machines just need new brushes and a little TLC so it is possible to make it work as is. Regardless, top of the line equipment, you won't get a machine in the same ballpark for twice that.

A Motor-generator 10EE requires 3 phase to run. Since 3 phase is not readily available in residential power, typically a rotary phase converter is used to power these. In short a rotary phase converter (RPC) uses a 3 phase motor as self-contained 3 phase generator. It requires a 3 phase motor to be used as an "idler", typically of twice the horse power that you're trying to run, and some peripheral electronics (switches, contactors and capacitors). The main advantage of an RPC is it can power more than one machine, although possibly not at the same time. This would allow you to run the Bridgeport and the Monarch from the same RPC.

A variable frequency drive (VFD) is a motor sophisticated piece of electronics that includes a microcontroller/computer, and generates 3 phase power through a frequency range. An appropriate VFD can generate that 3 phase power using residential single phase power input. Normally 3 phase motors turn at a speed dictated by the frequency of the power line (60Hz in the U.S.) and by their internal construction. So the motors turn at one speed. A VFD allows a 3 phase motor to be run at a speed range from about 1/3 the speed to 2x the speed. That range depends on the motor, and may be greater. The VFD senses what is going on with the motor, and has to be wired directly to the motor with some controls attached to the VFD, so a VFD generally only works with one motor. You'd need a VFD for each piece of equipment. But it gives you some improved options on selecting speed.

Last edited:

- Joined

- Sep 28, 2013

- Messages

- 4,306

I'd personally avoid buying a 10EE if I were new to machining, but free, why not? Hopefully it all works as they are a constant source of long and interesting threads on people fixing them, but if it does they're supposed to be one of the very best toolroom lathes you can get.

Sounds like a no brainer and probably this years biggest "you suck" award Might be worth spending some of the money they didn't cost you on a rigger though, unless you have some friends/ acquaintances that have experience moving heavy machinery.

Might be worth spending some of the money they didn't cost you on a rigger though, unless you have some friends/ acquaintances that have experience moving heavy machinery.

Sounds like a no brainer and probably this years biggest "you suck" award

- Joined

- Jan 31, 2016

- Messages

- 11,446

After reading up on these machines , they seem to be considered junk on other websites . BUT , being the nice guy that I am , I would consider removing them from your posession for a small fee , maybe gas money .

- Joined

- Oct 14, 2014

- Messages

- 1,970

Could you explain the VFD, 3 phase motor, and then you said it can run off single phase?

I thought that the MG drive had a 3 phase motor already, and therefore it cannot be ran single phase unless you changed the entire drive, I could be misunderstanding how the drive works though.

This has been done on a HUGE number of machines. You get a slightly larger 3 phase motor, used. (or the Bridgeport's motor is just fine) EBay is your friend. Also electrical surplus places. Then get a VFD that run on single phase. Almost all of them do, some advertise this ability many do not. There's a bit of control wiring, confusing if you have never done electrical, but there are a couple fellas here to hold your hand. here's one of my 10EE builds https://www.hobby-machinist.com/threads/monarch-10ee-rebuild-10hp-vfd-no-backgear.92017/

I am a HUGE fan of this route. I have two 10EEs this way, two manual milling machines, two CNC milling machines, a CNC lathe, an air compressor, and a bandsaw all with VFDs running single phase input. I am far from the only one that loves this route for hobby machines in a residential power situation.

An MG set, or motor generator set, has a motor driving a generator. Some have replaced the 3 phase driver motor with a single phase unit on the 10EE. I personally would not suggest this route - you still got an antique DC drive to repair. Now there are purists on another forum that love keeping the old DC drive running and they will help you. practicalmachinst.com

Yes all the tooling is free.1) Go get them. Free, with tooling? If you don't get them and you do get involved in this with other machines, you'll soon realize what you passed up. Seriously, run, do not walk ...

2) The 10EE can be a challenge to fix up the electronics, especially in the MG section (from someone with degrees in electrical engineering). The schematic @mksj shows is from a 60's era, matches my 1964, not applicable to a motor generator machine. Switching it out with a 7.5/10 HP 3 phase motor, and an oversized VFD so it can run on single phase, is likely the best option if there are any challenges with that part of the drive. Don't mess with it if it works. That is probably a $2-3k endeavor. Sometimes the MG machines just need new brushes and a little TLC so it is possible to make it work as is. Regardless, top of the line equipment, you won't get a machine in the same ballpark for twice that.

A Motor-generator 10EE requires 3 phase to run. Since 3 phase is not readily available in residential power, typically a rotary phase converter is used to power these. In short a rotary phase converter (RPC) uses a 3 phase motor as self-contained 3 phase generator. It requires a 3 phase motor to be used as an "idler", typically of twice the horse power that you're trying to run, and some peripheral electronics (switches, contactors and capacitors). The main advantage of an RPC is it can power more than one machine, although possibly not at the same time. This would allow you to run the Bridgeport and the Monarch from the same RPC.

A variable frequency drive (VFD) is a motor sophisticated piece of electronics that includes a microcontroller/computer, and generates 3 phase power through a frequency range. An appropriate VFD can generate that 3 phase power using residential single phase power input. Normally 3 phase motors turn at a speed dictated by the frequency of the power line (60Hz in the U.S.) and by their internal construction. So the motors turn at one speed. A VFD allows a 3 phase motor to be run at a speed range from about 1/3 the speed to 2x the speed. That range depends on the motor, and may be greater. The VFD senses what is going on with the motor, and has to be wired directly to the motor with some controls attached to the VFD, so a VFD generally only works with one motor. You'd need a VFD for each piece of equipment. But it gives you some improved options on selecting speed.

Thank you for the in depth explanation of the 3 phase MG drive and VFDs. I am still torn on VFD vs. RPC (If i was to do RPC I planned on buying one built, say 5hp for around 500$ is what ive seen, correct me if im wrong). However It seems like the VFD route is very popular.

- Joined

- Feb 25, 2021

- Messages

- 3,129

Couple quick comments:Yes all the tooling is free.

Thank you for the in depth explanation of the 3 phase MG drive and VFDs. I am still torn on VFD vs. RPC (If i was to do RPC I planned on buying one built, say 5hp for around 500$ is what ive seen, correct me if im wrong). However It seems like the VFD route is very popular.

You can't run the 10EE with a VFD unless you replace the entire motor-generator guts with a new motor (which you may end up doing if there are problems). You may want a slightly bigger RPC than 5 HP, say 7.5HP, to run the 10EE? That's a close call, 5HP may work fine. The bridgeport would definitely benefit from a VFD conversion as it would reduce messing with the belts for speed changes.

How much can you find out about the current status of the machines? Were they in a hobby shop? If so how were they powered there? Is the previous owner available to ask?

In regards to rigging and moving these machines. I dont think i would have any issues moving/transporting them... the issue i do have is where they are located and how to get them down to the ground/trailer. They have to be removed out of a bay, which is about 4 feet above ground level.

Any ideas? I was thinking about partial disassembling (at least on the mill).

Any ideas? I was thinking about partial disassembling (at least on the mill).