- Joined

- Aug 1, 2022

- Messages

- 137

So I got a “best offer” for a plate type ball turner. For ~$40, I figured it would cost me more procuring all the materials to start from scratch.

I removed the round base and decided to use a piece of 12L14 (3-1/4”x2”) round stock to make the piece that goes in hole where the compound mounts.

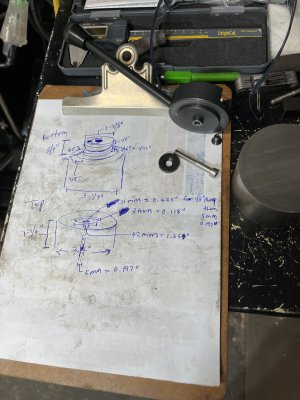

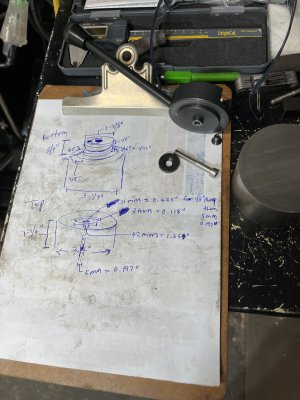

Here is the quick drawing I jotted down for this:

I machined the tapered interface to the saddle based the dimensions taken from the bottom of the coumpound.

I then flipped the bar stock over in the chuck and machined it to fit the piece of the ball turning attachment that turns.

Since I’m not too good at measuring, I did a few test fits to check the tool height and faced it down a little at a time until I got it to line up with a live center.

Ball turning attachment finished:

Now I need to test it. I chucked up a piece of brass in my 5c collet system (there’s another post detailing the making of the hand wheel draw tube) and proceeded to make a brass ball oil plug. My Heavy 10 had been missing one oil plug since I acquired it. Gotta tie up loose ends…

I modeled the new oil plug off of the one that I still had, which stayed put because it had been painted over by the previous owner of my lathe.

I then parted it and flipped it over in the 5c collet to finalize the diameter of the section that goes in and to Dremel the slit for the oil wick.

The new one is on the left.

Installed

I removed the round base and decided to use a piece of 12L14 (3-1/4”x2”) round stock to make the piece that goes in hole where the compound mounts.

Here is the quick drawing I jotted down for this:

I machined the tapered interface to the saddle based the dimensions taken from the bottom of the coumpound.

I then flipped the bar stock over in the chuck and machined it to fit the piece of the ball turning attachment that turns.

Since I’m not too good at measuring, I did a few test fits to check the tool height and faced it down a little at a time until I got it to line up with a live center.

Ball turning attachment finished:

Now I need to test it. I chucked up a piece of brass in my 5c collet system (there’s another post detailing the making of the hand wheel draw tube) and proceeded to make a brass ball oil plug. My Heavy 10 had been missing one oil plug since I acquired it. Gotta tie up loose ends…

I modeled the new oil plug off of the one that I still had, which stayed put because it had been painted over by the previous owner of my lathe.

I then parted it and flipped it over in the 5c collet to finalize the diameter of the section that goes in and to Dremel the slit for the oil wick.

The new one is on the left.

Installed

Last edited: