Hi

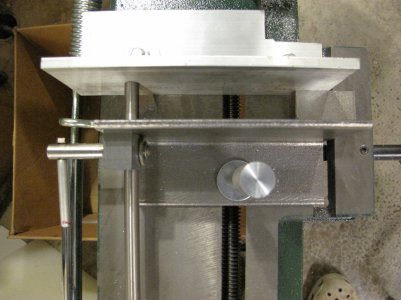

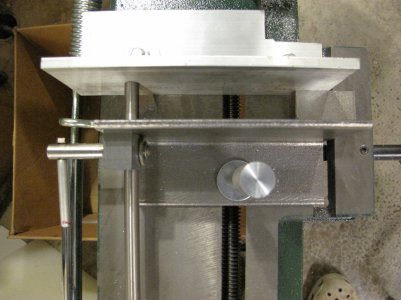

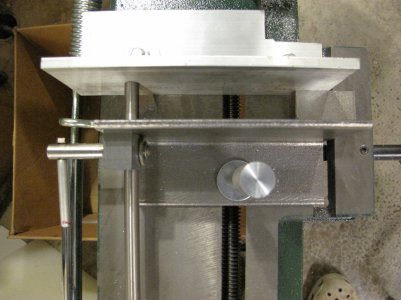

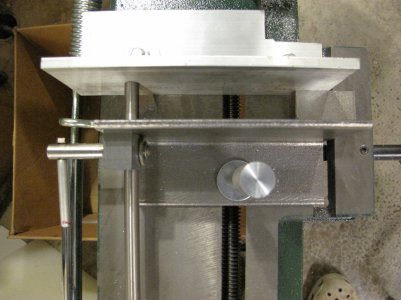

So I bought this "el cheepo" Busy Bee small 4x6 vertical & horizontal saw same as HF and other cheep saws out there and first thing as most folks notice is that this thing is horrible to cut any small peaces so I change the sliding jaw completely made it larger and longer and extended it towards the blade added sliding rod that is adjustable to the size of the material, also change the non movable jaw with the angle aluminum and also extended it closer to the blade so it would support better a smaller peaces looks good and so far good results, this idea was taken from the pictures I have seen on this forum someone did something very similar to this I just try to duplicated it and make it fit my own purpose

here are few photos of what it looks like

Paul

So I bought this "el cheepo" Busy Bee small 4x6 vertical & horizontal saw same as HF and other cheep saws out there and first thing as most folks notice is that this thing is horrible to cut any small peaces so I change the sliding jaw completely made it larger and longer and extended it towards the blade added sliding rod that is adjustable to the size of the material, also change the non movable jaw with the angle aluminum and also extended it closer to the blade so it would support better a smaller peaces looks good and so far good results, this idea was taken from the pictures I have seen on this forum someone did something very similar to this I just try to duplicated it and make it fit my own purpose

here are few photos of what it looks like

Paul