Bill,

First question: Do we want to get these couplings now ? we can make the spindle end 3/4" for mounting.

Second Question: Do we want to make a standard grinding spindle with a taper on the end to mount the arbor or make the spindle all one piece and machine the end for the wheel?

If we make the taper then we could make an arbor with balance weights on the rear. And seeing the price of a ready made arbor.....

....I say we can make the arbor and the balance system.

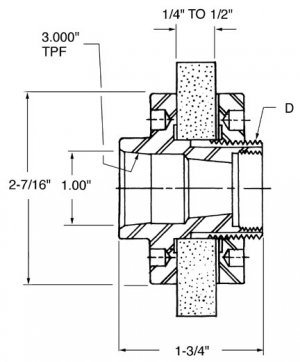

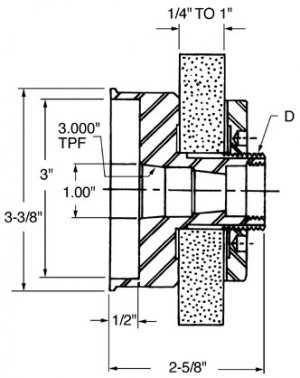

This is a representation of a simple arbor with no balance system.

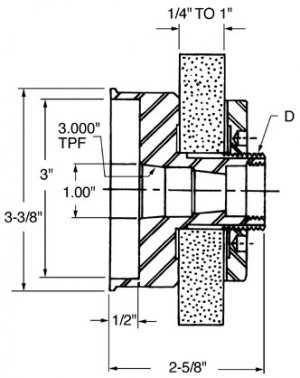

This is a representation of an arbor with a shroud to cover the spindle nose to keep crap out.

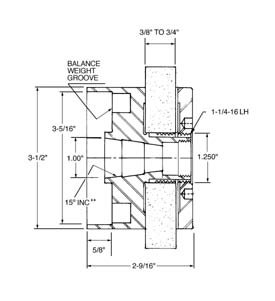

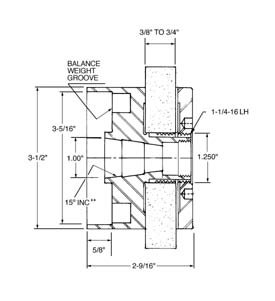

This is a representation of one with a balance weight groove.......This one gets my vote

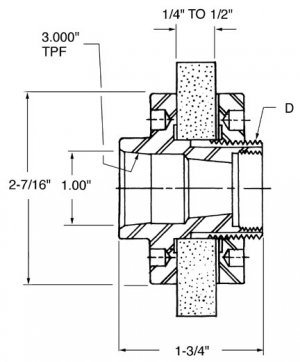

The other option is to machine the end of the spindle to accept a wheel. Simpler but no balance feature.

ANYONE GOT ANY OPINIONS HERE?

....I say we can make the arbor and the balance system.

....I say we can make the arbor and the balance system.