I think you'll be ok with the standard. Using this calculator, (

http://www.1728.org/mtrtrq.htm) I get, I get the torque on that part to be just under 16ft-lb (assuming 30hp, 10k RPM).

Doing some back-of the envelope calculations (worst case). Lets assume that the shaft is in bad shape, and all of the torque is being transmitted by one corner of the square, and that the contact area is only 1/16" wide. We'll also assume that our radius is about 3/16". So, the force on that 1/16" wide would be

Torque = force * distance

so

force = Torque/distance

which gives me

16ft-lb/0.1875in*12in/1ft = 1024lb

You say the material is 0.25" thick, so the contact area is 0.25"*0.0625" = 0.016 in^2.

Pressure on that area would be 1024lb/0.016in^2 = 65536psi.

Yield strength for 4140 is listed as 65ksi for annealed, and 125ksi normalized. That's close, way closer than I would normally want to see, but then again, we have looked at the _absolute_ worst case.

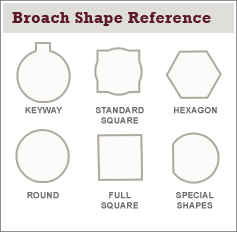

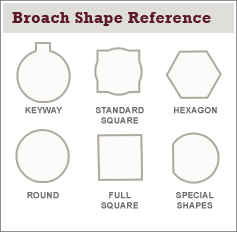

I'll see if I can come up with a better model for this, all my books are at home, and this is just an off the cuff guess. Regardless, I think the standard would work for you. The corners handle most of the torque anyway (if you think about it, the force is tangent to the flats at the middle, which basically means they support no torque, other than what they can support by friction). For me, I would be more concerned with getting a tight fit. If it loosens up and you get banging, the stresses will go way up.