-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A couple questions about the Model C

- Thread starter tcarboy

- Start date

I've seen those, and I'm curious about people's experience with them. I have a 3D printer and a couple rolls of filament sitting around, so it's not a stretch to get one started. Are they durable enough to last through normal usage? Is there a filament type that works better than others?

I mostly print in PLA, but I have spools of ABS and PETG I've been meaning to experiment on. If one of those is a better choice it'll give me a reason to get back to dialing in my settings

I mostly print in PLA, but I have spools of ABS and PETG I've been meaning to experiment on. If one of those is a better choice it'll give me a reason to get back to dialing in my settings

- Joined

- Sep 8, 2011

- Messages

- 12

Really.. lets be a little more dramatic! If the pin is whats bent then I agree with removing pin. My last two 9a's had the arm of the cover bent. And YES I did straighten/bend them back.Or you could just try straightening it while in the cover.

but first ask yourself “Do I Feel Lucky?

Did your SB9C come with change gears & a thread dial?

- Joined

- Mar 21, 2018

- Messages

- 1,606

What temperature does babbitt melt at? I was thinking whether or not to hit it with a torch before I started bending it, I would have felt like a real idiot if things started melting unexpectedly.

It's lower than lead -more like a hard solder. It ranges from about 425ºF to 475ºF. Catch the old stuff in an old tuna can so that you can reuse it.

Thanks! I'll keep that in mind. My 2 year old woke up early from his nap, so there was no time for fireworks. I just popped it in the vice, got a little extra leverage, and nudged the pin back into place. No cracks, no fractures, and everything lines up like it ought toIt's lower than lead -more like a hard solder. It ranges from about 425ºF to 475ºF. Catch the old stuff in an old tuna can so that you can reuse it.

I'm two posts in, and I'm already seeing parallels. I've also got a non-original motor, not wired to run in reverse. Looking forward to see where it takes you.

- Joined

- Mar 3, 2020

- Messages

- 506

I guess that joke fell on deaf ears, my bad.Really.. lets be a little more dramatic! If the pin is whats bent then I agree with removing pin. My last two 9a's had the arm of the cover bent. And YES I did straighten/bend them back.

i guess everybody hasn’t heard of Dirty Harry.

cheers

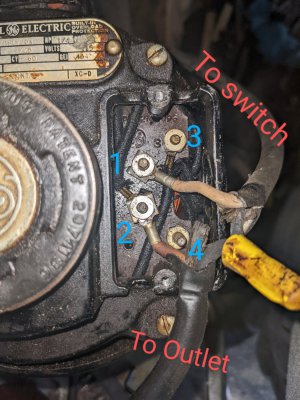

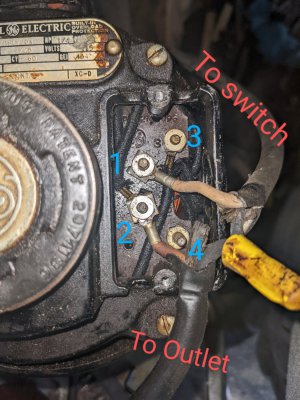

Thank you all so much for your replies, it was all really helpful. So helpful, in fact, that I have more questions. I don't know if the motor I have in the lathe is original, but I know for sure the wiring isnt.

GE Model 5KC47AB490DX, 1/4hp, single phase.

There's no wiring diagram on the motor. It's currently wired for single direction, with an On/Off toggle. I've tried looking online for documentation, but no luck.

Is it possible to wire this for forward/reverse? Would I need a drum switch, and if so how would I wire it? And maybe more importantly, is it safe to keep running this motor with all that cloth wrapped wiring in there?

GE Model 5KC47AB490DX, 1/4hp, single phase.

There's no wiring diagram on the motor. It's currently wired for single direction, with an On/Off toggle. I've tried looking online for documentation, but no luck.

Is it possible to wire this for forward/reverse? Would I need a drum switch, and if so how would I wire it? And maybe more importantly, is it safe to keep running this motor with all that cloth wrapped wiring in there?