Hello,

I recently picked up a Model C from Craigslist. It's a big step up from the Unimat SL-1000 I've been toying around with. I've been reading through How to Run a Lathe, and I bought a guide on disassembly and renovation, and I've got a couple questions I wanted to ask the community.

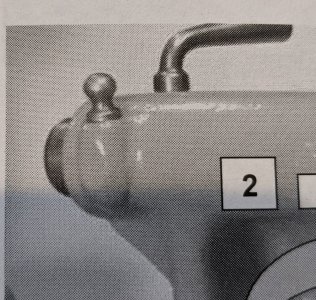

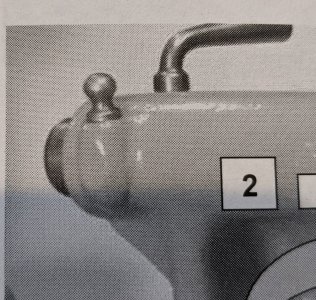

I've seen this ball-headed pin on the tailstock opposite the quill lock in a lot of images, and my lathe didn't come with it. I haven't seen it named in the parts diagrams. Is this just a mounting point on the tailstock for some accessory? Or am I missing something important?

The hinge pin on the headstock gear cover is bent, enough that the spindle rubs against the cover when it's fully closed. What is the best way to go about fixing this? Can I bend the pin back to square? Or is it hardened and likely to snap if I try? Should I drill it out and turn a replacement once I get the lathe cleaned up and running again? Should I just look for a new cover on EBay?

I appreciate any help you all can provide.

-Tom

I recently picked up a Model C from Craigslist. It's a big step up from the Unimat SL-1000 I've been toying around with. I've been reading through How to Run a Lathe, and I bought a guide on disassembly and renovation, and I've got a couple questions I wanted to ask the community.

I've seen this ball-headed pin on the tailstock opposite the quill lock in a lot of images, and my lathe didn't come with it. I haven't seen it named in the parts diagrams. Is this just a mounting point on the tailstock for some accessory? Or am I missing something important?

The hinge pin on the headstock gear cover is bent, enough that the spindle rubs against the cover when it's fully closed. What is the best way to go about fixing this? Can I bend the pin back to square? Or is it hardened and likely to snap if I try? Should I drill it out and turn a replacement once I get the lathe cleaned up and running again? Should I just look for a new cover on EBay?

I appreciate any help you all can provide.

-Tom