- Joined

- Oct 5, 2016

- Messages

- 78

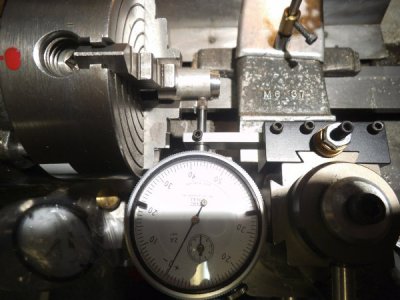

Mounted the 4 jaw chuck, and went to school indicating a work piece. Watched a couple of videos before attempting the dance. Using two chuck keys machinist make it look like a no brainier.

Made a few feeble attempts to copy the moves, going around the chuck (laughing @ myself) in circles. Started to understand the concept, and developed my own routine using a single chuck key.

Came together nicely, I'll go back a few times just to indicate some different size and shape of bar. I like the 4 jaw and the goal is to use it most of the time.

A question, other than the expense & holding power of a 6 jaw chuck are there other advantages to know about?

Greg

Made a few feeble attempts to copy the moves, going around the chuck (laughing @ myself) in circles. Started to understand the concept, and developed my own routine using a single chuck key.

Came together nicely, I'll go back a few times just to indicate some different size and shape of bar. I like the 4 jaw and the goal is to use it most of the time.

A question, other than the expense & holding power of a 6 jaw chuck are there other advantages to know about?

Greg