This is just a fun post to show what you can do when you are CHEAP!

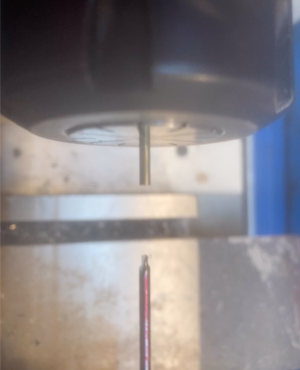

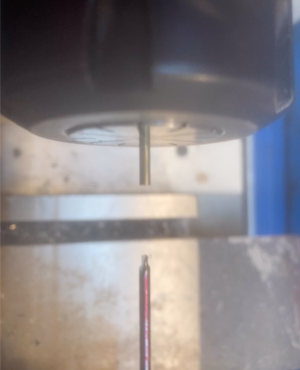

The picture is a blower resistor for an 05 Grand Caravan. $25 at local parts store. My wife calls from work and says the blower only works on high, quit while she was driving. I replaced the resistor and checked it out. Everything was fine, all the speeds. I last replaced it about 4 years ago. My wife calls me up again and tells me she only has high speed and the blower motor is screaming. A quick Youtube check says that the fan motor will start drawing too much and burn out the resistor. $70 for the motor at the local parts store. I have replaced blower motors on lots of Dodge vans over the years, but this by far was the worst, Several hours later, a broken tab and new language invented, the motor is in. I looked over the resistor to find a 1/4" area of wire missing. I dug out both ends to what shows above. The wires sticking up are wrapped around the resistor. You can see the ridges. I scrapped and cleaned the wire ends.

I dug out a piece of .078 brass rod from a Chinese assortment I bought last year. I know better but I tried anyway to touch a #55 drill to the end and of course it skittered all around. Holding my breath, I faced off the rod and then center drilled it. The center drill was in a pile of used stuff from years ago. You know "I just cleaned out Grandpa's toolbox and it is worth a fortune".

I don't have a micro drilling setup yet, It's on the list so I chucked up my small drill setup into the large drill chuck and cranked it in. It Worked! Time to breath again.

Now comes the fun part. I took my parting tool and parted it off. I can buzz right through 2" of 1018, but something this small???? I didn't take a picture and it parted perfectly!!!! Caught it in a cup and Yahtzee! (guess where that came from)?

The little tab is the burr that was left after parting. I know a REAL you-tuber would turn it around and deburr and chamfer it, but this old boy knows when it is time to call it quits. The wires were twisted together and the brass tube squeezed shut. I have a good 30 minutes of running now, so I will consider this done. Lets see, a 12" lathe, ER32 collet chuck and collets, two different size drill chucks and misc???? An easy $3K to avoid buying another $25 resistor.

If any of you decide to replace the motor, I would suggest finding a little Gumby Girl. The little small girls who are double jointed and tie themselves up into knots and make you feel pain watching them. Me, I got jammed between the door and passenger seat and almost didn't make it back out.

Hope you enjoy!

The picture is a blower resistor for an 05 Grand Caravan. $25 at local parts store. My wife calls from work and says the blower only works on high, quit while she was driving. I replaced the resistor and checked it out. Everything was fine, all the speeds. I last replaced it about 4 years ago. My wife calls me up again and tells me she only has high speed and the blower motor is screaming. A quick Youtube check says that the fan motor will start drawing too much and burn out the resistor. $70 for the motor at the local parts store. I have replaced blower motors on lots of Dodge vans over the years, but this by far was the worst, Several hours later, a broken tab and new language invented, the motor is in. I looked over the resistor to find a 1/4" area of wire missing. I dug out both ends to what shows above. The wires sticking up are wrapped around the resistor. You can see the ridges. I scrapped and cleaned the wire ends.

I dug out a piece of .078 brass rod from a Chinese assortment I bought last year. I know better but I tried anyway to touch a #55 drill to the end and of course it skittered all around. Holding my breath, I faced off the rod and then center drilled it. The center drill was in a pile of used stuff from years ago. You know "I just cleaned out Grandpa's toolbox and it is worth a fortune".

I don't have a micro drilling setup yet, It's on the list so I chucked up my small drill setup into the large drill chuck and cranked it in. It Worked! Time to breath again.

Now comes the fun part. I took my parting tool and parted it off. I can buzz right through 2" of 1018, but something this small???? I didn't take a picture and it parted perfectly!!!! Caught it in a cup and Yahtzee! (guess where that came from)?

The little tab is the burr that was left after parting. I know a REAL you-tuber would turn it around and deburr and chamfer it, but this old boy knows when it is time to call it quits. The wires were twisted together and the brass tube squeezed shut. I have a good 30 minutes of running now, so I will consider this done. Lets see, a 12" lathe, ER32 collet chuck and collets, two different size drill chucks and misc???? An easy $3K to avoid buying another $25 resistor.

If any of you decide to replace the motor, I would suggest finding a little Gumby Girl. The little small girls who are double jointed and tie themselves up into knots and make you feel pain watching them. Me, I got jammed between the door and passenger seat and almost didn't make it back out.

Hope you enjoy!