- Joined

- Jan 11, 2013

- Messages

- 1,821

Hey Folks

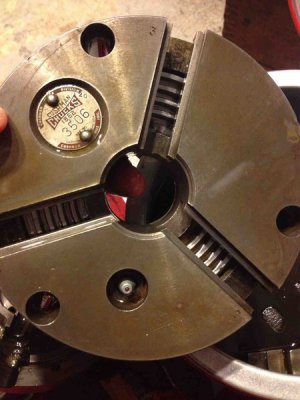

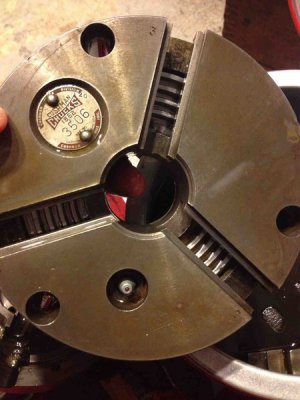

A beautiful Cushman 6 inch 3 jaw chuck that came with this Heavy Ten I got last week.

It's a little stiff, and the previous owner mentioned it could probably use a rebuild, so today is the day. I have some pics below of the disassembly. It is a much nicer chuck than I have owned, as it came apart a totally different way than the "semi-steel" chucks I am used to! Hah hah

I DIGRESS-

It has a factory grease fitting on top.

(EDIT- I found out after writing this that it MAY be an oil Zerk fitting)

Can I use the same PTFE/Teflon grease I would use in my backgear/cone pulley? I have heard of "chuck grease", but don't know if it is different at all.

I want to reassemble it packed already, and also want have the right stuff on hand to keep it up. It sure would help if I could just keep one grease gun at the lathe for everything.

Thanks folks!

Bernie

Grease fitting

When I finally found the seam, I really had to rap hard with this little brass hammer through the rag to split it:

I never had a chuck that split in the middle like this! Very tight tolerance... I could barely see the seam:

I should have shown the dirty scroll and parts first!! But I got too carried away. Suffice it to say, despite this being a well cared for and visually "clean" and high quality chuck, it was dirty, gunky, with hardened grease inside. Only some small brass swarf on the scroll:

A beautiful Cushman 6 inch 3 jaw chuck that came with this Heavy Ten I got last week.

It's a little stiff, and the previous owner mentioned it could probably use a rebuild, so today is the day. I have some pics below of the disassembly. It is a much nicer chuck than I have owned, as it came apart a totally different way than the "semi-steel" chucks I am used to! Hah hah

I DIGRESS-

It has a factory grease fitting on top.

(EDIT- I found out after writing this that it MAY be an oil Zerk fitting)

Can I use the same PTFE/Teflon grease I would use in my backgear/cone pulley? I have heard of "chuck grease", but don't know if it is different at all.

I want to reassemble it packed already, and also want have the right stuff on hand to keep it up. It sure would help if I could just keep one grease gun at the lathe for everything.

Thanks folks!

Bernie

Grease fitting

When I finally found the seam, I really had to rap hard with this little brass hammer through the rag to split it:

I never had a chuck that split in the middle like this! Very tight tolerance... I could barely see the seam:

I should have shown the dirty scroll and parts first!! But I got too carried away. Suffice it to say, despite this being a well cared for and visually "clean" and high quality chuck, it was dirty, gunky, with hardened grease inside. Only some small brass swarf on the scroll:

Last edited: