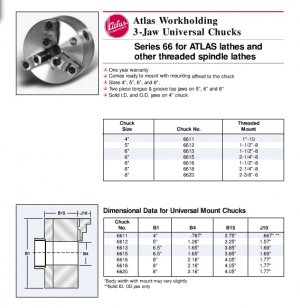

:thinking:I am just starting to get my Atlas 10"-48" up and running. I have finally gotten most of my tooling and I found sites saying that a check bar is useful in resetting the tail stock when I need to. I started making the bar and I could not get my 3 jaw chuck to work correctly. It would not let me unchuck the metal. I could only rotate the chuck key one turn. I took the chuck off the lathe and started to disassembled the chuck. I got it apart and found hardened lube every where. I had to chisel the lube from everywhere. Yes I had chips, grit, and hard chunks of lube in the workings. What found in the ring was a tooth from the chuck gear stuck in the ring. The only thing that I had done to the chuck was fill it with oil and wiped it down. The tooth slot looks like it must have happened some time ago, no shinny metal. The chuck only has the numbers 6613-1 on it. No manufacture name. Long question short. Can I get a part, have it made, take my mig and weld a tooth and regrind, or pitch it? I am going to try to post a pic. I know you have ideas. Lets hear what you have to say!

As always thanks!

As always thanks!

Last edited: