- Joined

- Dec 12, 2012

- Messages

- 109

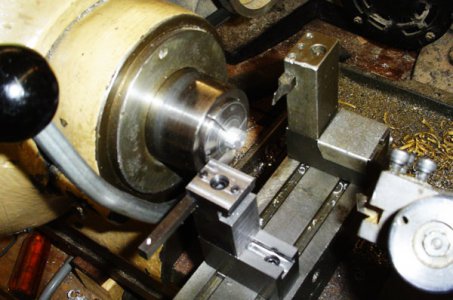

Long story short, at work we ended up having Studs manufactured for our customer in the incorrect length (too long). They can't be re-purposed so they're essentially scrap. I got the idea to turn them into 2/3 scale valve spindles and hand them out to all the employees of the company as desk ornaments (about 20 people). I chose the valve spindle because valve manufacturing and overhaul represents a big part of our business.

The Studs are 4140 heat treated to about 35 HRC. Last night I made the first one to figure out the tooling and schedule of operations. Now that I have that figured out I can tackle the rest like a production line.

Of note, I milled the 4 flats using a fly cutter mounted in a 5C collet on the lathe, with the collet closer I built recently (see previous postings a page or two back). I have a milling attachment but opted to mount the spindle in a quick change tool holder (one with a v-groove for a boring bar) and used the QCTP. Gotta say I was pretty excited to see that in action! I'll post pictures of the production run and milling setup in the next few days.

The Studs are 4140 heat treated to about 35 HRC. Last night I made the first one to figure out the tooling and schedule of operations. Now that I have that figured out I can tackle the rest like a production line.

Of note, I milled the 4 flats using a fly cutter mounted in a 5C collet on the lathe, with the collet closer I built recently (see previous postings a page or two back). I have a milling attachment but opted to mount the spindle in a quick change tool holder (one with a v-groove for a boring bar) and used the QCTP. Gotta say I was pretty excited to see that in action! I'll post pictures of the production run and milling setup in the next few days.