I bought this lathe about 2 years ago and found some issues. Having another working lathe, this has sat on the back burner for some time. I'm back into it full swing now with some work coming up that the old 9 is just a tad small for.

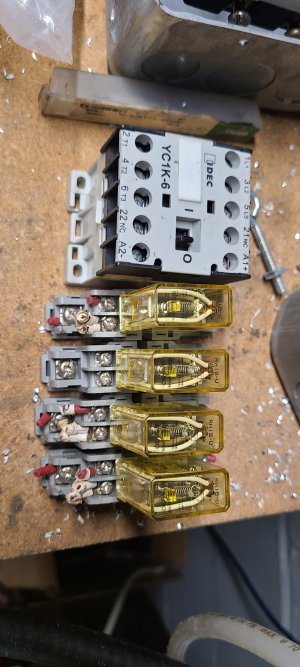

To recap on another thread, I bought this knowing there were some issues, but for the money, it seemed to be a good gamble. I replaced motor and electrical with a new 2HP 3 Phase motor and VFD. Then it sat after finding a crazy vibration, manifesting at the motor, that ruined any type of decent finish.

I finally pulled the tailstock apart and found the key that locks the ram to be badly worn. Luckily a replacement was found at Grizzly for $3 and will be inbound along with new way wipers and a few other odds and ends.

The vibration issue had me stumped for a bit and working back and removing the chuck, indicating the headstock spindle, jack shaft, and motor spindle, to considering a motor replacement, I was at a loss for what was causing the problem. The motor was brand new, albeit from ebay, but i couldnt put my finger on the shutter and vibration.

As a last ditch effort to dropping $300 on another motor, i found a few posts and related articles that mentioned belts. Belts?? Really, a v-belt that appeared almost new and visually in good condition would be the culprit? YES!!! To my amazement when i replaced the motor to jackshaft pully belt, all that crazy shutter and vibration was reduced to almost nill. I'm amazed that a $35 link belt from Harbor Freight fixed the issue. I definitely learned something today about a belts contribution to the proper operation of a machine.

Needless to say, I will be replacing the headstock spindle to jackshaft belt and can only imagine that will take any remaining vibration away from the machine and has given me much needed motivation to continue to bring this lathe back to some of its former glory.

Another example of taking a risk, spending some time and polishing what appears to be turd, can take the place and save of spending a few $5K on a comparable new machine.

To recap on another thread, I bought this knowing there were some issues, but for the money, it seemed to be a good gamble. I replaced motor and electrical with a new 2HP 3 Phase motor and VFD. Then it sat after finding a crazy vibration, manifesting at the motor, that ruined any type of decent finish.

I finally pulled the tailstock apart and found the key that locks the ram to be badly worn. Luckily a replacement was found at Grizzly for $3 and will be inbound along with new way wipers and a few other odds and ends.

The vibration issue had me stumped for a bit and working back and removing the chuck, indicating the headstock spindle, jack shaft, and motor spindle, to considering a motor replacement, I was at a loss for what was causing the problem. The motor was brand new, albeit from ebay, but i couldnt put my finger on the shutter and vibration.

As a last ditch effort to dropping $300 on another motor, i found a few posts and related articles that mentioned belts. Belts?? Really, a v-belt that appeared almost new and visually in good condition would be the culprit? YES!!! To my amazement when i replaced the motor to jackshaft pully belt, all that crazy shutter and vibration was reduced to almost nill. I'm amazed that a $35 link belt from Harbor Freight fixed the issue. I definitely learned something today about a belts contribution to the proper operation of a machine.

Needless to say, I will be replacing the headstock spindle to jackshaft belt and can only imagine that will take any remaining vibration away from the machine and has given me much needed motivation to continue to bring this lathe back to some of its former glory.

Another example of taking a risk, spending some time and polishing what appears to be turd, can take the place and save of spending a few $5K on a comparable new machine.