I just hooked up my phase converter And got the rotation correct. My problem is all the oil is low. The Lubrication plate on the lathe said to use high grade machine oil viscosity 275-290 seconds saybolt at 100 degrees for the headstock and gearbox. The carriage and apron vactra oil #2. Power traverse cylinder oil viscosity 155-165 at 210 degrees. The lathe has been sitting for 15 years I just want to make sure it is Lubricated properly before I use it. Thanks for your help.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1954 American pacemaker lathe 14x54

- Thread starter rick1933

- Start date

Nice lathe. I’m guessing that’s for more than just home hobby work?

just to have fun with the price was right. I need to learn how to use it all in time . My problem is I'm not sure what kind of oil for the headstock and gearbox. I was told vactra #4 for headstock and gearbox and vactra #2 for everything else. Maybe you can help. This lube chart is what I found on the side .??

Attachments

- Joined

- Aug 2, 2020

- Messages

- 562

Interesting.Nice lathe. I’m guessing that’s for more than just home hobby work?

Sent from my iPhone using Tapatalk

I would say it depends...

I have a 14.5 x 30 in my home/hobby shop.

I think the swing is perfect and another foot or two of bed length would have suited me fine.

I just hooked up my phase converter And got the rotation correct. My problem is all the oil is low. The Lubrication plate on the lathe said to use high grade machine oil viscosity 275-290 seconds saybolt at 100 degrees for the headstock and gearbox. The carriage and apron vactra oil #2. Power traverse cylinder oil viscosity 155-165 at 210 degrees. The lathe has been sitting for 15 years I just want to make sure it is Lubricated properly before I use it. Thanks for your help.I NEED HELP trying to find out what oil will work in headstock and gear box i was told vactra #4?? And vactra #2 for everything else??? Will that work

Attachments

- Joined

- Jul 6, 2022

- Messages

- 498

Interesting.

I would say it depends...

I have a 14.5 x 30 in my home/hobby shop.

I think the swing is perfect and another foot or two of bed length would have suited me fine.

I guess my thinking is that something of that weight and footprint would generally be for larger projects. Out of interest, what sort of projects do you do that take advantage of the larger size of your lathe?

Sent from my iPhone using Tapatalk

- Joined

- Apr 23, 2018

- Messages

- 6,538

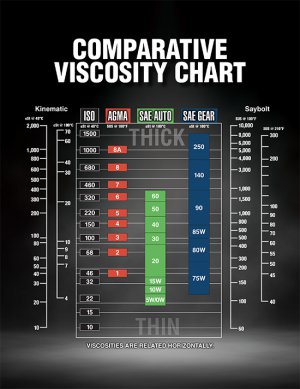

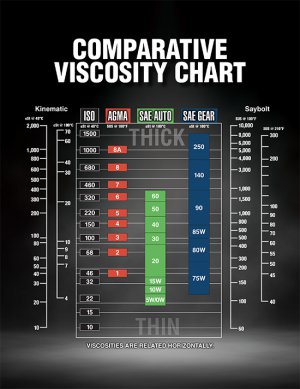

Here's "the" chart for comparing viscosity specs. Saybolt units are on the right hand scale.

I use Mobil, so I pull their TDS sheets to make the final decision if the oil is right. The range of viscosity is pretty wide, but the list of additives included/excluded is top level critical, ,and depends a lot on your machine's components.

I use Mobil, so I pull their TDS sheets to make the final decision if the oil is right. The range of viscosity is pretty wide, but the list of additives included/excluded is top level critical, ,and depends a lot on your machine's components.

- Joined

- Sep 28, 2022

- Messages

- 142

I have a 1941 16x54 American Pacemaker. The last two digits of the serial number will give you the year it was built. The correct oil for the headstock is Mobil DTE Heavy-Medium. For the feedbox and the apron, it is an ISO 68 way oil. I prefer the Schaeffer 160 moly way lube which is an ISO 68 with the addition of moly and the original tackifiers. I can actually feel the reduction in friction with this oil as opposed to when Vectra way oil is used.I just hooked up my phase converter And got the rotation correct. My problem is all the oil is low. The Lubrication plate on the lathe said to use high grade machine oil viscosity 275-290 seconds saybolt at 100 degrees for the headstock and gearbox. The carriage and apron vactra oil #2. Power traverse cylinder oil viscosity 155-165 at 210 degrees. The lathe has been sitting for 15 years I just want to make sure it is Lubricated properly before I use it. Thanks for your help.

A couple of other related tips:

When the oil in the headstock is at the correct level, be careful about lifting the tailstock end too high. It doesn’t take that much off level for oil to run into the clutch housing and out the back of the large pully shaft as the seal there is only a labyrinth. It can sure make a mess quickly before you can figure out what’s going on - speaking from experience.

Also, when I start mine for the first time after it has sat a while, I usually run through this routine to ensure that oil has had chance to reach everywhere before I get started. I put the headstock in neutral between medium and high range. And then I engage the clutch which starts the oil pump. On the Pacemaker, oiling in the headstock is achieved by filling a large reservoir and channels in the top of the head. This in turn runs oil over the gear train and bearings. I know oil has reached everything when I see a trickle of oil through the flow sight glass. Just be careful to be sure that you are stable in the neutral position as slipping into gear would be bad with the clutch engaged.

I rebuilt mine so I have been through most of the machine. If I can help with any additional questions on the oiling system (or anything else) and how it works, just ask.

- Joined

- Aug 2, 2020

- Messages

- 562

The old saying is it's easier to do small work on a big lathe than big work on a small lathe.I guess my thinking is that something of that weight and footprint would generally be for larger projects. Out of interest, what sort of projects do you do that take advantage of the larger size of your lathe?

Sent from my iPhone using Tapatalk

Off the top of my head... the square end on the adapter I made for my drill press is about 10 3/4" corner to corner.

The other photo shows a clamp for the injector pump kill cable on my tractor.

I haven't really needed more length C to C but sometimes it would be nice to slide the tail stock farther out of the way and/or store the steady rest on the end of the ways. I think about 42" C to C would be about perfect.