- Joined

- Jun 6, 2015

- Messages

- 283

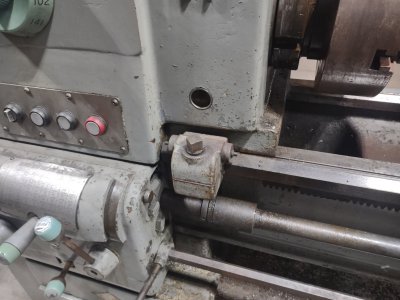

Picked this up last Friday. Everything works, but the chuck is stuck on the spindle. After an hour I got the nut loose, but no go on the chuck. I would assume the idea is to use the nut to push the chuck off. I went this route, but no luck. Any suggestions? I thought about heating the chuck thread area up to help release it from the taper, but I haven't yet.

I also would like to get the coolant pump running, is this worth it or should I go with some.sort of replacement?

I'm also in the market for a steady rest if anyone has one laying around. I've attached a few pictures of the machine.

Jason

I also would like to get the coolant pump running, is this worth it or should I go with some.sort of replacement?

I'm also in the market for a steady rest if anyone has one laying around. I've attached a few pictures of the machine.

Jason

Attachments

-

IMG_20230409_192354397.jpg405.1 KB · Views: 53

IMG_20230409_192354397.jpg405.1 KB · Views: 53 -

IMG_20230407_162904157.jpg451.5 KB · Views: 50

IMG_20230407_162904157.jpg451.5 KB · Views: 50 -

IMG_20230409_192430161.jpg293.6 KB · Views: 47

IMG_20230409_192430161.jpg293.6 KB · Views: 47 -

IMG_20230409_192442241.jpg394.7 KB · Views: 42

IMG_20230409_192442241.jpg394.7 KB · Views: 42 -

IMG_20230409_192437881.jpg427.5 KB · Views: 43

IMG_20230409_192437881.jpg427.5 KB · Views: 43 -

IMG_20230409_192414162.jpg439.6 KB · Views: 45

IMG_20230409_192414162.jpg439.6 KB · Views: 45 -

IMG_20230409_192408990.jpg509.4 KB · Views: 43

IMG_20230409_192408990.jpg509.4 KB · Views: 43 -

IMG_20230409_192359662.jpg349.2 KB · Views: 50

IMG_20230409_192359662.jpg349.2 KB · Views: 50