- Joined

- Mar 23, 2021

- Messages

- 357

This post will be part five of the thread that I started here: https://www.hobby-machinist.com/threads/1440gt-upgrades-and-additions.96854/

When I ordered my 1340GT back in March of '21 I knew that I wanted to incorporate a solid tool post. And in June when I acquired my RF-45 mill it became doable!

So I contacted David Best and asked him about his design. He most graciously offered to make me a set of Fusion 360 drawings that would incorporate the Aloris QCTP that I had acquired from a member here. So he sent me a request for the specific dimensions of my tool post and in a few days he sent me back a set of very detailed plans!

When I began machining I had no idea that I would end up with a 1440GT instead, so the tool post was milled to within about .020" of the final height to fit the 1340GT. Not a problem though as it was very easy to make a plate for the bottom of the tool post the proper height to make up the difference between the two lathes. I ended up making the spud on my solid tool post in a way that fastens the bottom plate/extension to the tool post so it stays in place when I swap out for the compound slide.

I was lucky enough to have gotten a newer model Aloris QCTP with the 1440GT, so I now have two Aloris BXA QCTPs. This makes it very convenient as I don't have to swap the QCTP from the solid tool post to the compound when switching back and forth. At least at this point in time I like threading with the compound versus the solid tool post.

It should be noted that the two Aloris QCTPs that I have are not identical in dimension, and differ enough that modifications would be necessary to use one versus the other. They differ in overall height by .007" and the registration pin placement on the base is just enough off that my new QCTP will not fit the solid tool post as the registration pin hole was drilled based on the dimension of the older QCTP. I suspect that the specifications for the Aloris QCTP have not changed, it's simply a matter of lot variance, but that's just my speculation.

David, in his never ending generosity and sharing nature, will join in on this post with his plans.

Thanks again David for all the assistance on this project!

Here's some photos:

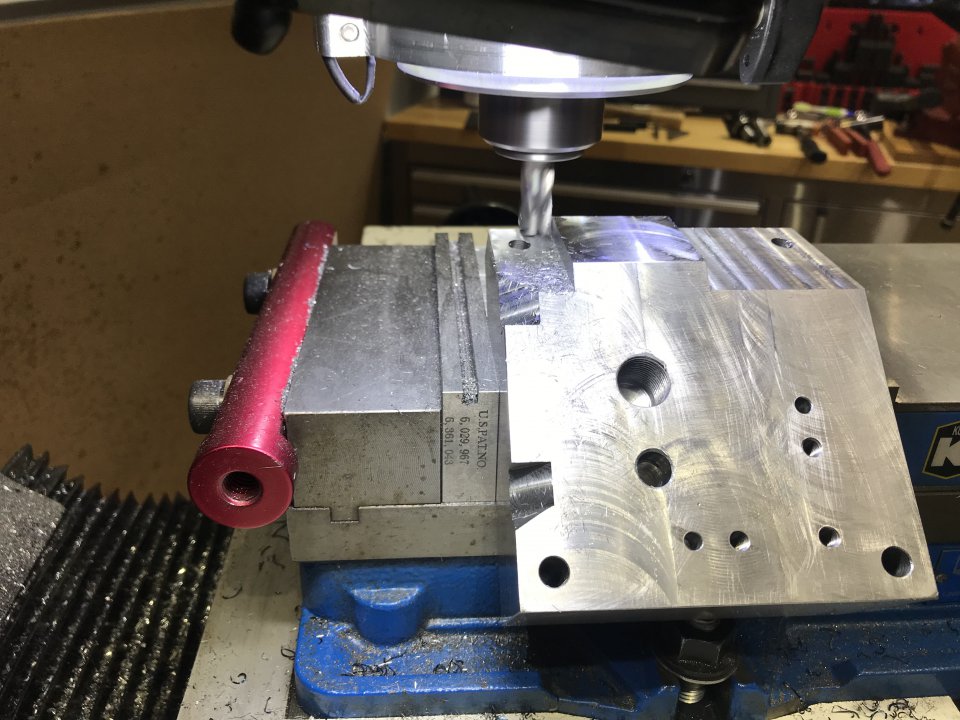

This is the only photo I can find of my machining process, but David has a flickr page that he can link to where he has a lot more photos of when he made his. He made his on the same model mill that I made mine on. In fact, the mill that I have was setup by David for the original owner, but that's another story!

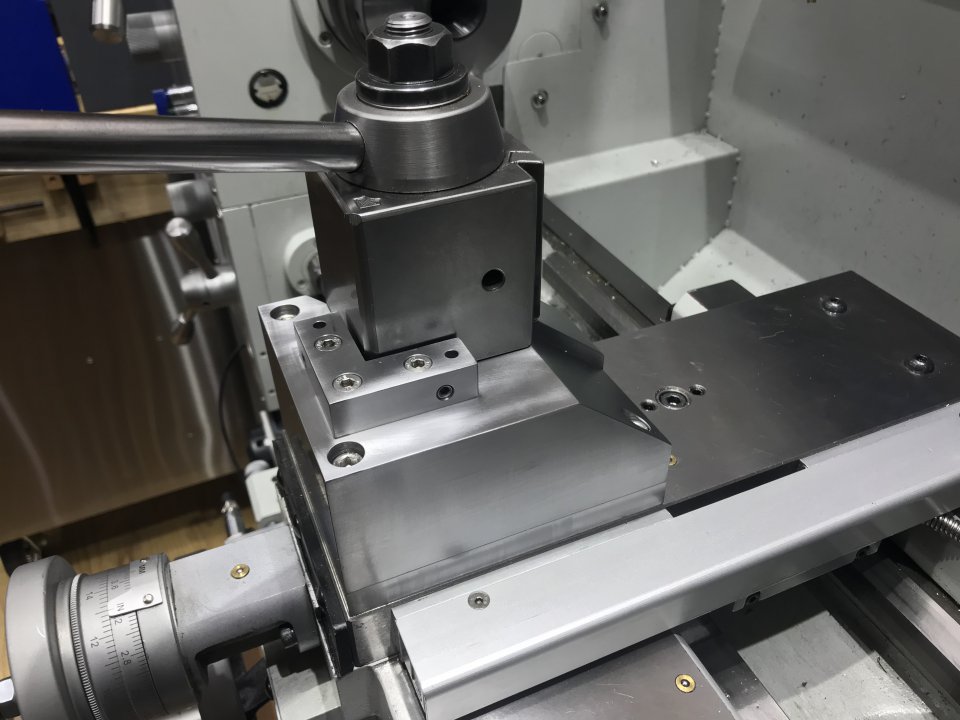

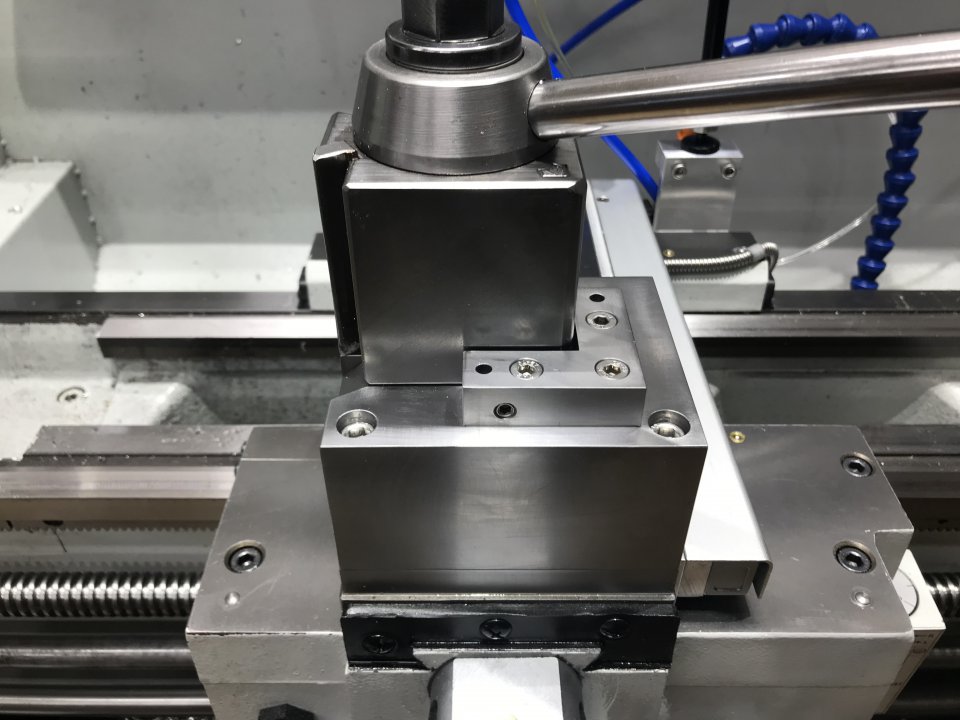

The rest of the photos are the tool post once I finished the new base to raise it for the 1440's additional height and got it mounted on the lathe:

In case anyone is interested, the QCTP above looked like this before I decided that I would rather have it polished. The name plate fell off when I had the QCTP in a vise to disassemble it for cleaning and lubrication and I didn't see a need to put it back on. It was used of course and I had no idea how much use it had gotten. Turns out that the innards showed no wear that I could detect. This photo was the sellers from the add:

Here's the QCTP that came with the 1440. It's obviously a newer manufacture date item:

So there you have it!

When I ordered my 1340GT back in March of '21 I knew that I wanted to incorporate a solid tool post. And in June when I acquired my RF-45 mill it became doable!

So I contacted David Best and asked him about his design. He most graciously offered to make me a set of Fusion 360 drawings that would incorporate the Aloris QCTP that I had acquired from a member here. So he sent me a request for the specific dimensions of my tool post and in a few days he sent me back a set of very detailed plans!

When I began machining I had no idea that I would end up with a 1440GT instead, so the tool post was milled to within about .020" of the final height to fit the 1340GT. Not a problem though as it was very easy to make a plate for the bottom of the tool post the proper height to make up the difference between the two lathes. I ended up making the spud on my solid tool post in a way that fastens the bottom plate/extension to the tool post so it stays in place when I swap out for the compound slide.

I was lucky enough to have gotten a newer model Aloris QCTP with the 1440GT, so I now have two Aloris BXA QCTPs. This makes it very convenient as I don't have to swap the QCTP from the solid tool post to the compound when switching back and forth. At least at this point in time I like threading with the compound versus the solid tool post.

It should be noted that the two Aloris QCTPs that I have are not identical in dimension, and differ enough that modifications would be necessary to use one versus the other. They differ in overall height by .007" and the registration pin placement on the base is just enough off that my new QCTP will not fit the solid tool post as the registration pin hole was drilled based on the dimension of the older QCTP. I suspect that the specifications for the Aloris QCTP have not changed, it's simply a matter of lot variance, but that's just my speculation.

David, in his never ending generosity and sharing nature, will join in on this post with his plans.

Thanks again David for all the assistance on this project!

Here's some photos:

This is the only photo I can find of my machining process, but David has a flickr page that he can link to where he has a lot more photos of when he made his. He made his on the same model mill that I made mine on. In fact, the mill that I have was setup by David for the original owner, but that's another story!

The rest of the photos are the tool post once I finished the new base to raise it for the 1440's additional height and got it mounted on the lathe:

In case anyone is interested, the QCTP above looked like this before I decided that I would rather have it polished. The name plate fell off when I had the QCTP in a vise to disassemble it for cleaning and lubrication and I didn't see a need to put it back on. It was used of course and I had no idea how much use it had gotten. Turns out that the innards showed no wear that I could detect. This photo was the sellers from the add:

Here's the QCTP that came with the 1440. It's obviously a newer manufacture date item:

So there you have it!

Last edited: