- Joined

- Dec 3, 2013

- Messages

- 1,844

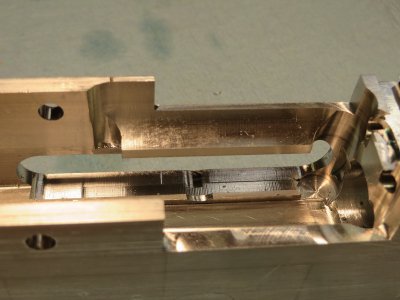

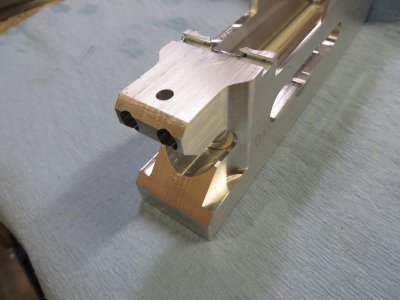

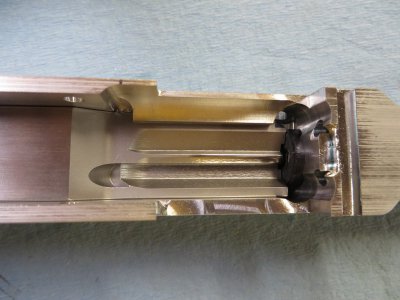

First major mistake. There is an undercut inside the ejection port for bolt clearance. Part of the undercut needs to be flush with the inside face of the pocket where the bolt slides. To be cautious I reset the z zero and in the process didnt pay attention to the tool being set on tool #1 instead of tool #0. When I ran the program the machine thought the tool zero was the face of the spindle and crashed the tool holder into the part before I could hit the e-stop. I believe I caught it before doing any damage to the machine. I have run some test parts and and so far everything seems okay. The 300lb head is direct driven with a 4200 in/oz servo so I'm pretty sure something would break before it stalled.

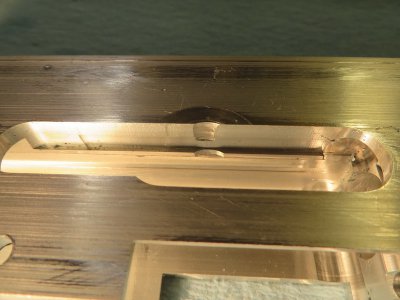

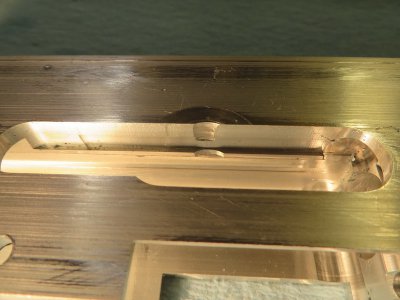

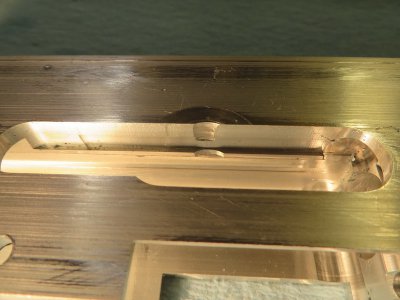

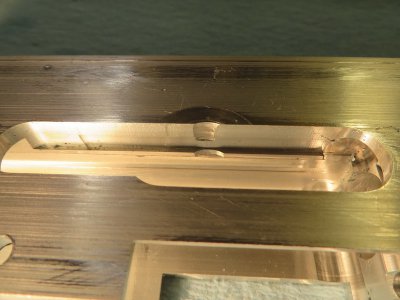

The mark on the inside of the ejection port is where the tool shaft, which is wider than the t-slot cutter, struck the part. Fortunately this only cosmetic.

The mark on the inside of the ejection port is where the tool shaft, which is wider than the t-slot cutter, struck the part. Fortunately this only cosmetic.