- Joined

- Feb 2, 2020

- Messages

- 149

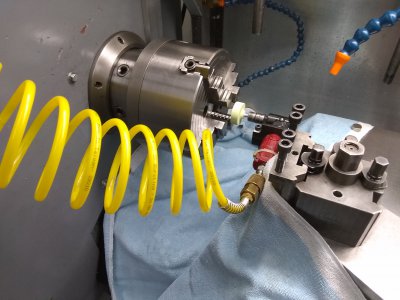

I have a 10" Cushman 36E3 3 jaw chuck with an L0 mount. It has bolt on reversible jaws. I like the chuck but it has some runout. I can tap the piece around and get it around 0.005". I had the idea of checking the backing plate but this chuck is all one piece. How can one tear it down and try to reduce runout? I have a 4 jaw chuck but it's 8".

I have checked the taper and made sure it was clean and smooth. I could loosen the collar and tap around the chuck but I would like to disassemble the chuck for cleaning. The lathe hadn't been used in years.

I have checked the taper and made sure it was clean and smooth. I could loosen the collar and tap around the chuck but I would like to disassemble the chuck for cleaning. The lathe hadn't been used in years.