-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1" Tool Holders Carbide insert Tooling

- Thread starter ddickey

- Start date

- Joined

- Nov 26, 2012

- Messages

- 1,307

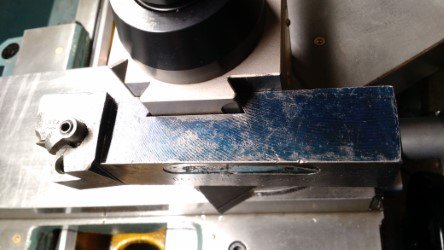

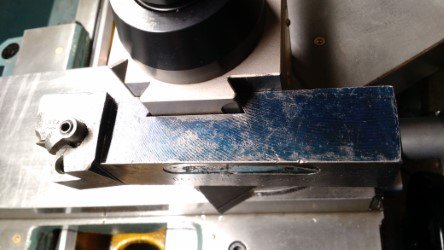

Got it done. Dovetail came out very nice. I used an old carbide endmill I had and pretty much destroyed it I think. Then took a few light passes with a new carbide rougher then milled the dovetails with my home made cutter that uses a carbide insert. I was a little surprised at how well it cut. The insert loosened up once but no damage was done. I may have gone just a hair to deep in the depth but it fits really nice. Now if i could get the pin out of the other holder to try it out.

Last edited:

4

4GSR

Forum Guest

Register Today

Yeah, That's kind of an obsolete holder now days.Boy that's depressing. This is a facing tool only.

I have another one if someone wants it check the for sale forum.

You have to be very careful what you buy out there. Especially one's that have heavily damaged seats that don't support the shim or insert. And also ones that used semi obsolete inserts. Sometimes, you can get a lifetime supply of inserts for almost nothing, provided you find a holder, or make a holder for.