- Joined

- Feb 7, 2013

- Messages

- 2,487

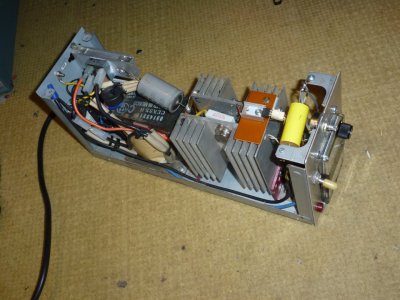

The cold days of winter are good for an electronic project or two so decided to build up a power supply for the electronics bench.

An old uninteruptable power supply case served well for the project's cabinet as well as a heavy 120/15 volt AC transformer.

I used an LM317 voltage regulator and 4 2N3771 NPN power transistors in my design and added meters for both voltage and

current. I used Ohm's Law to determine the series resistance for the volt meter and parallel resistance for the ammeter and

tested the meters against my trusty old Simpson 260 VOM. It's great to have something to power testing radios or other

electronic equipment, charge batteries or just have power for a bit of experimenting .

.

I was lucky to have two large heat sinks in my box of junk as the mounting of the power transistors was relatively easy that way. I could add a fan

if it proves to be necessary and the heat sinks get too hot with a heavy current draw.

The potentiometer allows one to select the voltage needed for the application. I used some banana plug

sockets so I can use the test leads from a VOM or make up some heavier ones if needed. My total

investment is less than $20 and that was for the voltage regulator and power transistors. Everything

else was stuff I had on hand in my boxes of electronic junk. The project did get me into the shop for

several hours to drill some large holes for the meters and get them mounted on an aluminum plate.

An old uninteruptable power supply case served well for the project's cabinet as well as a heavy 120/15 volt AC transformer.

I used an LM317 voltage regulator and 4 2N3771 NPN power transistors in my design and added meters for both voltage and

current. I used Ohm's Law to determine the series resistance for the volt meter and parallel resistance for the ammeter and

tested the meters against my trusty old Simpson 260 VOM. It's great to have something to power testing radios or other

electronic equipment, charge batteries or just have power for a bit of experimenting

.

. I was lucky to have two large heat sinks in my box of junk as the mounting of the power transistors was relatively easy that way. I could add a fan

if it proves to be necessary and the heat sinks get too hot with a heavy current draw.

The potentiometer allows one to select the voltage needed for the application. I used some banana plug

sockets so I can use the test leads from a VOM or make up some heavier ones if needed. My total

investment is less than $20 and that was for the voltage regulator and power transistors. Everything

else was stuff I had on hand in my boxes of electronic junk. The project did get me into the shop for

several hours to drill some large holes for the meters and get them mounted on an aluminum plate.