- Joined

- Jul 13, 2014

- Messages

- 1,051

https://houston.craigslist.org/tls/6177054325.html

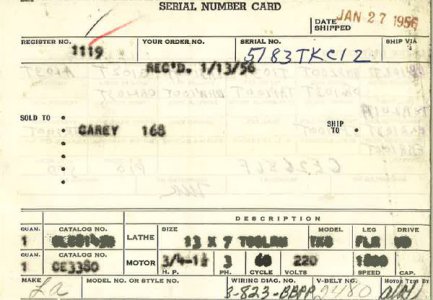

For Sale: 13" long bed South Bend lathe with taper attachment. I purchased this lathe 17 years ago with the hope of restoring it. When I was looking at these machines this was the best one I found. It is still in very good condition. I have made quite a few parts on it. If you go to Ebay you will see fully restored machines like this over $4k. This is classic American iron, and it sure feels like it. I purchased it from a gentleman who owned it for nearly thirty years, and said he purchased it from the original owner. It was never in a school. I recently bought a larger machine and no longer have room for this. Everything works, and the lead screw looks perfect. Some way wear close to the chuck as expected, but the scraping is still visible over half the bed length, and on the cross slide ways. It had a 3 phase motor when I bought it, so I replaced with a new fan cooled Century 1.5 HP single phase motor. So, it will run on standard household 220. I have a full set of Armstrong tool holders and rocker post, and I added a BXA quick change post with a set of tool holders. Tailstock is MT3 taper and a live center goes with it. 1-3/8" through Camlock spindle with 6" 4-jaw and 8" 3-jaw chuck included as well. 8 speeds 40-940 rpm and 48 standard thread pitches. I have the book and a scan of the original purchase order showing a manufacture date of 1956. Asking $1800. Text is best

For Sale: 13" long bed South Bend lathe with taper attachment. I purchased this lathe 17 years ago with the hope of restoring it. When I was looking at these machines this was the best one I found. It is still in very good condition. I have made quite a few parts on it. If you go to Ebay you will see fully restored machines like this over $4k. This is classic American iron, and it sure feels like it. I purchased it from a gentleman who owned it for nearly thirty years, and said he purchased it from the original owner. It was never in a school. I recently bought a larger machine and no longer have room for this. Everything works, and the lead screw looks perfect. Some way wear close to the chuck as expected, but the scraping is still visible over half the bed length, and on the cross slide ways. It had a 3 phase motor when I bought it, so I replaced with a new fan cooled Century 1.5 HP single phase motor. So, it will run on standard household 220. I have a full set of Armstrong tool holders and rocker post, and I added a BXA quick change post with a set of tool holders. Tailstock is MT3 taper and a live center goes with it. 1-3/8" through Camlock spindle with 6" 4-jaw and 8" 3-jaw chuck included as well. 8 speeds 40-940 rpm and 48 standard thread pitches. I have the book and a scan of the original purchase order showing a manufacture date of 1956. Asking $1800. Text is best