- Joined

- Dec 18, 2013

- Messages

- 2,354

Project: Machine a T nut for my new Aloris BXA QCTP to fit the Grizzly G4003G lathe

Glacern 2.5" 45 deg face mill - I loaded it with Iscar SEHT 1204AFN IC928 PVD TiAlN coated inserts. Iscar says "recommended for interrupted cut and heavy operations". Spindle speed 400-600 rpm, .050 depth of cut. I'm quite happy with the Glacern face mill, this included face milling 2" wide material in a single pass. These Iscar inserts chugged right through the steel, I could have increased spindle speed further but didn't feel like listening to the mill gear head go WHAAAAAAA at umpteen decibels. I fed it manually with the hand wheel. I got nice blue chips when fed faster, I backed off the feed to shiny chips when I took a hot chip to the arm. These Iscar inserts won't produce a mirror finish but the finish was pretty decent considering I didn't even bother with taking a finish pass, I just hogged it to size. The inserts still look new.

ETM ER32 collet set - So the 1/2 end mill turned true and machined fine but the OD of the collect holder wobbles noticeably. I had one of these before years ago and I don't remember it wobbling, I will look into this further tomorrow. The Hertel coated 1/2 inch end mill chewed through the steel at .356 depth of cut .050 per pass with no difficulty at all and produced a decent finish. I had the spindle speed down fairly slow, I only have one of these end mills for steel and wanted to make sure I finished this T nut project. I'd buy more of these now that I have used them.

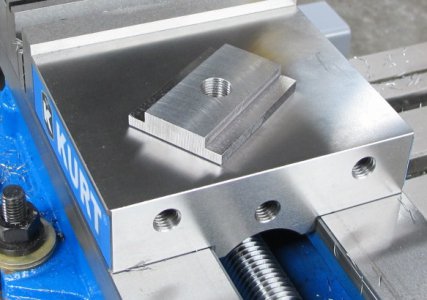

Here I have milled the T nut blank to width to try out the Glacern face mill.

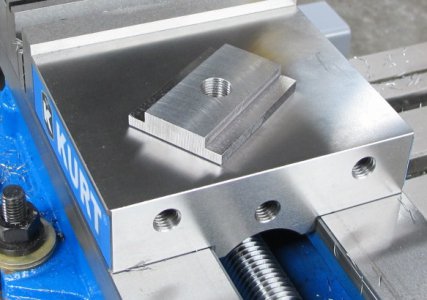

The facing is now complete.

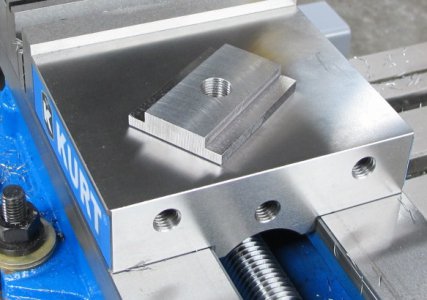

Here's the final machining of the T nut.

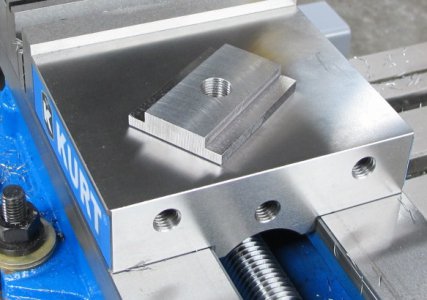

All done, it fits the Grizzly G4003G perfectly! Tomorrow I can finally install the Aloris QCTP and try out the new beast Aloris #71 parting tool!

Glacern 2.5" 45 deg face mill - I loaded it with Iscar SEHT 1204AFN IC928 PVD TiAlN coated inserts. Iscar says "recommended for interrupted cut and heavy operations". Spindle speed 400-600 rpm, .050 depth of cut. I'm quite happy with the Glacern face mill, this included face milling 2" wide material in a single pass. These Iscar inserts chugged right through the steel, I could have increased spindle speed further but didn't feel like listening to the mill gear head go WHAAAAAAA at umpteen decibels. I fed it manually with the hand wheel. I got nice blue chips when fed faster, I backed off the feed to shiny chips when I took a hot chip to the arm. These Iscar inserts won't produce a mirror finish but the finish was pretty decent considering I didn't even bother with taking a finish pass, I just hogged it to size. The inserts still look new.

ETM ER32 collet set - So the 1/2 end mill turned true and machined fine but the OD of the collect holder wobbles noticeably. I had one of these before years ago and I don't remember it wobbling, I will look into this further tomorrow. The Hertel coated 1/2 inch end mill chewed through the steel at .356 depth of cut .050 per pass with no difficulty at all and produced a decent finish. I had the spindle speed down fairly slow, I only have one of these end mills for steel and wanted to make sure I finished this T nut project. I'd buy more of these now that I have used them.

Here I have milled the T nut blank to width to try out the Glacern face mill.

The facing is now complete.

Here's the final machining of the T nut.

All done, it fits the Grizzly G4003G perfectly! Tomorrow I can finally install the Aloris QCTP and try out the new beast Aloris #71 parting tool!