........couldn't be any more or less cutting else a proper thread inverted V wouldn't be created with a 60° included angle to match the cutting tool V.....

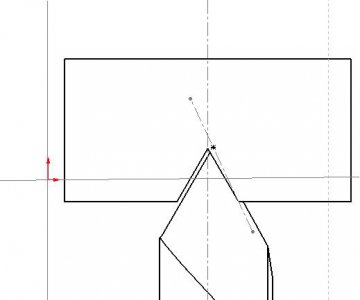

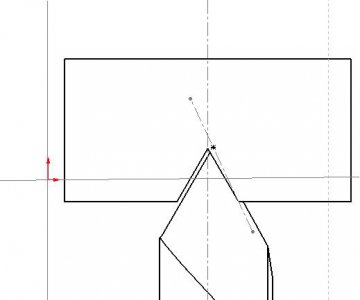

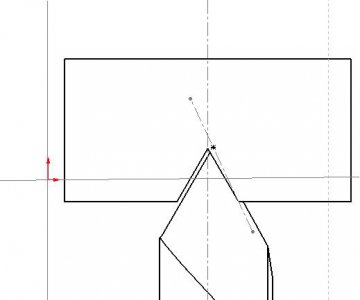

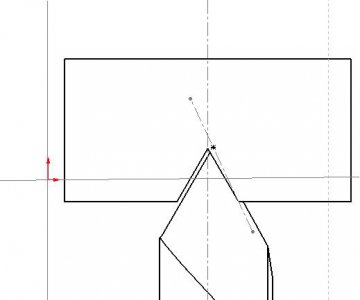

As I suggested, you are missing the point about the relationship of movement established by having the compound set at 29.5*. Yes the tool form does establish the thread profile, but by having the tool cut progress at not quite 30* it takes the majority of the cut on the left (leading) edge, and the right, (trailing) edge takes very light cuts. In the pic the V cut by the tool form is 60* but as can be seen by the dashed line the movement of the tool when set at less than 30* causes it to move in a marginal amount as well as left a greater amount. Causing the tool to take a heavier cut on the leading edge and a very fine cut on the trailing edge.

.......A 30° angled cutting tool edge and tip moving at an angle less than or more than 30° could not possibly be moving in parallel or in the same direction as the surface or profile of the inverted V that is supposed to be 30°.......

As the sketch illustrates, having the tool move in at an angle

less than 30* we do maintain the included angle of the form tool it just cuts less on the trailing edge. If the angle is set at or greater than 30* then the tool will only cut on the leading edge as it is sliding along or moving away from the trailing edge as it cuts progressively deeper, and this will result in a staircase effect on the trailing edge.

.......Not everyone teaches or supports the less-than-30° compound angle setting. In fact, many books do not even mention it. In my opinion, the reason that old meaningless practice persist is that it does not really create much of a drastic or perceivable difference to the final thread cut profile.

All the previous small discrepancies created by the wrong less-than-30° angle setting would just be wiped out by the next cutting step due to the fact that the cutting tool is actually a form tool ground to a 60° included angle ( symmetrical and 30° on each side). That 60° profile would just clean up any slight discrepancy created by the previous cut.

So, my point is, why not just use 30° and do it correct the first time?.....

No not everyone does teach or support it, but their may be more reasons than because you think it is myth. Cutting tools are much better nowadays, CNC machines may cut threads using different methods, the size and rigidity of the lathe may not permit heavier straight in cutting, the quality of the finished product may or may not have a bearing on the method, single point threading in my opinion is a dying art as the cheapness and availablity of threaded products can outweigh the cost of a production shop spending the time making something they can probably buy cheaper.

The point of it is to eliminate the staircase effect and reduce tool loading. The drastic and perceivable difference of leaving the staircase effect is that the right thread flank in most cases is the load bearing side of the thread and needs to be as smooth and accurate as possible.

.....compound less than 30° and still justify the reason or claim that it makes the tool cut only at the tip and the left side and none on the right side edge of the cutting tool .....

As I suggested in my reply earlier, you are not thinking about the progression of the tool. We are using the compound angle to establish a small amount of y axis movement and a greater amount of x axis movement resulting in cutting on

both sides of the tool.

It's either 30° or straight in at 90°, but 30° has an advantage of not creating too much cutting stress since only one side cuts as opposed to both sides for 90° .

I have yet to find a book that explains the 28°, 29° or 29 1/2° compound setting with good mathematical logic.

Perhaps in an ideal situation with every angle perfect, and we are talking measuring in seconds of degrees here then it

1) may be possible to have your tool ground to 60* +/- 0.0000

2) set your tool to be perpendicular to the work 90* +/-0.0000

3) set your compound to 30* +/-0.0000

and then have your tool sliding in perfectly parallel on the right flank and only cutting on the left flank.

Provided our machine is also perfect and has no defect.

But as we are not working to these levels of precision then with a

1) hand ground HSS tool, “eyeballed” for accuracy in a fish tail gauge

2) said fish tail gauge then “eyeballed” for presenting the tool at 90* to the work

3) compound “eyeballed” for 30*

then I would suggest that if anything is off 1 way or the other then the compound will be presenting the tool at something less or more than 30* +/- 0.0000.

Then we also need to take into allowance our worn dovetails, gibs backlash and other general wear on our workshop lathe.

As I doubt there would be many machinists, if at all a single 1 who gets their threading tools ground to the nth degree of perfection, and then uses lasers to ensure that they have the tool presented at 90* to the work and also uses a vernier protractor to establish that they have set the compound to 30* then I am of the opinion that “something in the realm of a bit less than 30*” is probably optimal.

Cheers Phil