- Joined

- Sep 20, 2012

- Messages

- 560

Here's another one.

Thanks Splat, hadn't seen that one.

I have some 3/4" Acetate rod that I could have used to do a similar job as shown there, but with my worn nut I thought would have had trouble milling the housing part, also there is not much room for one in the Atlas carriage.

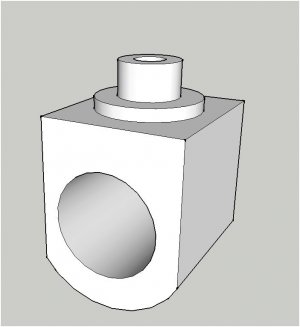

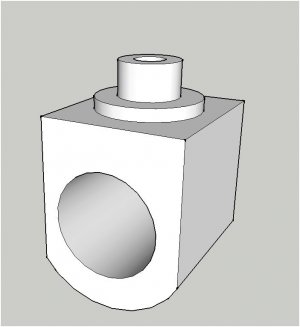

The more I think about it, I reckon a stepped spigot (so that the original type screw head could be used) and corresponding modified hole in the cross slide would be a worthwhile improvement for long term strength, summat like this. .

I will be trying this when i make the one for my turret slide..

Bernard