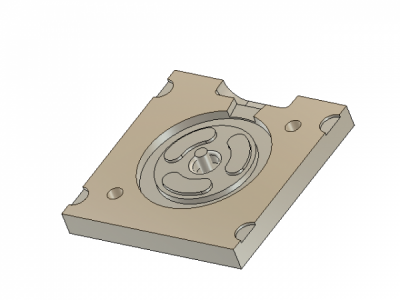

This semester I decided to take a page out of Lyle Peterson's (Tubalcain,mrpete222) play book and rather than turning flywheels I would attempt to cast them. But unlike Lyle's lead flywheels I had to be lead free. I also wanted to try casting the flywheels directly to the shaft forgoing the need for set screws. So I thought I'd try Zamak 3 which melts at 728F. Normally for gravity permanent molds Zamak 12 is preferred but my pot tops out at 750F which is too low for Zamak 12. I was concerned with the molds sticking so I opted for boron nitride lubricant/wash which has worked treat. The wash lasts a long time on the ladle. It generally has to be reapplied every 5 to 10 parts depending on wear.

The process is simple. The students turn a shaft to length and file a flat on one end. It works without the flat but it may turn during machining. They then insert the shaft into the warm mold and pour in the zinc (Zamak). Let it cool a minute, pop it out of the mold, and it's ready for the next pour. The students then cut off the sprue, paint it, and then turn it to final dimension.

Also just prior to the holiday break we milled a very simple mold of a snowflake design. By the end of the day we could do about one a minute. The electric melting pot worked great and acted as a holding furnace. I can't imagine trying to hold/control the temperature in the gas furnace all day. The students were amazed they could complete the ornament in about 5 minutes which included casting, fettling, drilling a hole, and bending the hanger. Good intro to simple wire forming jigs.

For those of you that haven't seen Lyle's video here is a link:

The process is simple. The students turn a shaft to length and file a flat on one end. It works without the flat but it may turn during machining. They then insert the shaft into the warm mold and pour in the zinc (Zamak). Let it cool a minute, pop it out of the mold, and it's ready for the next pour. The students then cut off the sprue, paint it, and then turn it to final dimension.

Also just prior to the holiday break we milled a very simple mold of a snowflake design. By the end of the day we could do about one a minute. The electric melting pot worked great and acted as a holding furnace. I can't imagine trying to hold/control the temperature in the gas furnace all day. The students were amazed they could complete the ornament in about 5 minutes which included casting, fettling, drilling a hole, and bending the hanger. Good intro to simple wire forming jigs.

For those of you that haven't seen Lyle's video here is a link: