- Joined

- Nov 27, 2012

- Messages

- 7,912

Some of this is from the other thread here. Mainly adding to my archive.

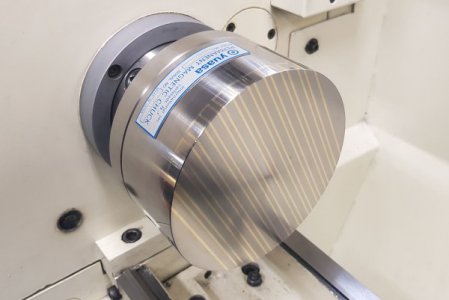

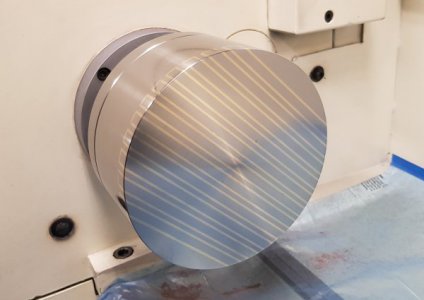

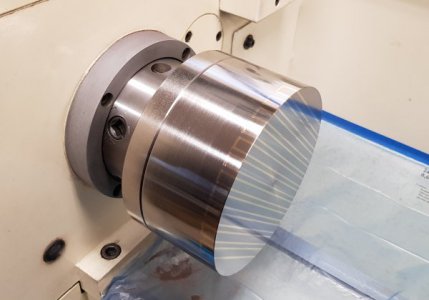

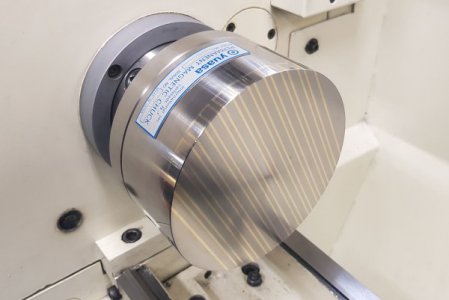

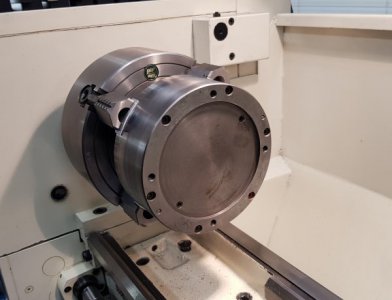

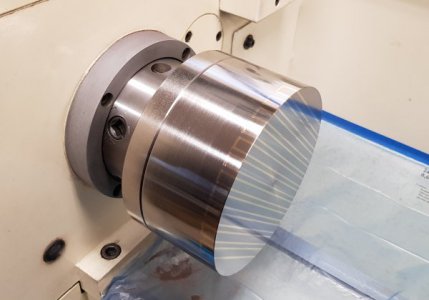

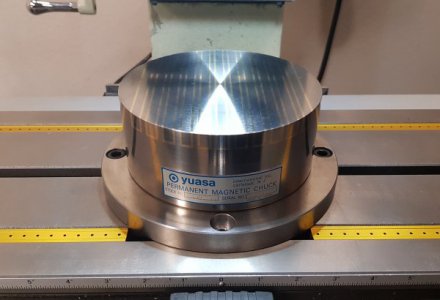

Got a 6.3" Yuasa round magnetic chuck a while back to use on the lathe. Mainly to work on thin parts & machine parts flat (parallel on both sides). Not meant to take heavy cuts (think surface grinder), just light skimming is what I'll be doing with it. I haven't got fully comfortable with how strong it will hold various sized parts yet but getting there. So far I'm happy to have this in my arsenal.

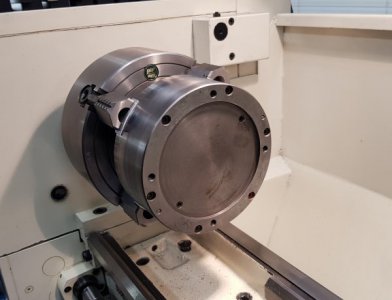

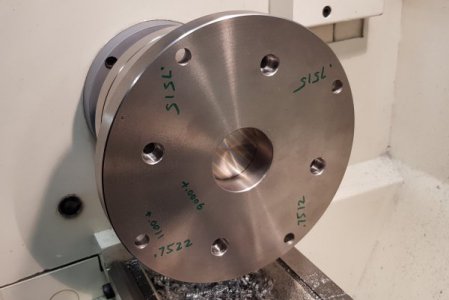

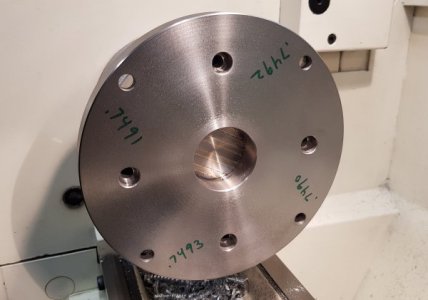

Used a South Bend branded 8" D1-4 back plate from Grizzly to mount it. Took quite a while to get it down to 6.3" but it was worth it.

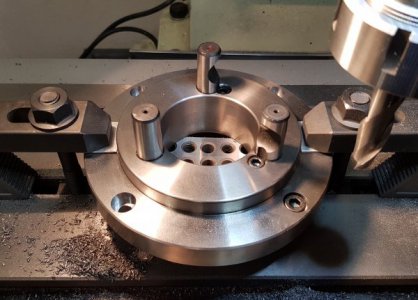

Here's how it looked when I got it.

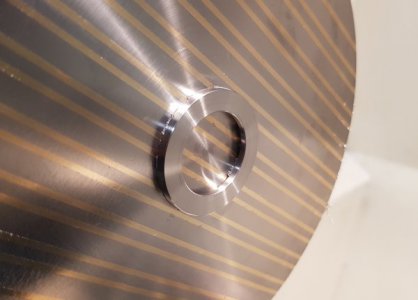

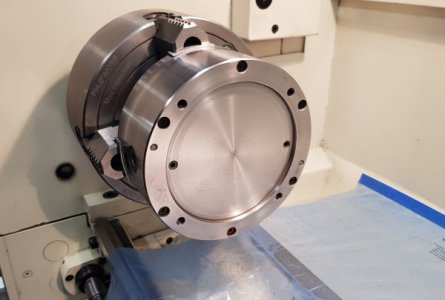

A bit of light sanding & scotchbrite cleaned it up very nice. I decided not to skim the face or grind it just yet.

Just with clean up it only had about .001" runout on the body & .0002" rounout on the face, +/- .0001" depending on where I measure it. Didn't see a need to face it at this time.

It came with the original key (square rather than hex like most others) but I wanted one with a bit longer handle. 7mm square keys are hard to find so I thought for sure I would have to make one. Found one from Myford, even coming from the UK it was a good price & good quality. Handle was way too long so I shortened it.

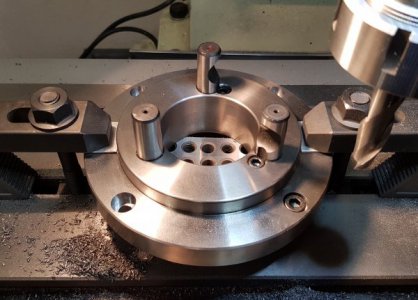

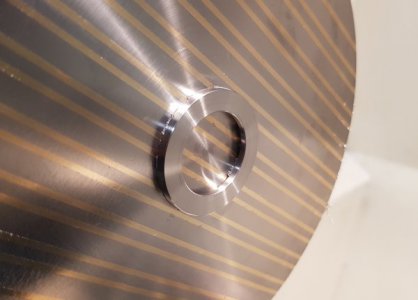

First thing I made. I needed a spacer for my slitting saw arbor. Wanted it as flat as possible so it wouldn't add any runout which was a success.

Got a 6.3" Yuasa round magnetic chuck a while back to use on the lathe. Mainly to work on thin parts & machine parts flat (parallel on both sides). Not meant to take heavy cuts (think surface grinder), just light skimming is what I'll be doing with it. I haven't got fully comfortable with how strong it will hold various sized parts yet but getting there. So far I'm happy to have this in my arsenal.

Used a South Bend branded 8" D1-4 back plate from Grizzly to mount it. Took quite a while to get it down to 6.3" but it was worth it.

Here's how it looked when I got it.

A bit of light sanding & scotchbrite cleaned it up very nice. I decided not to skim the face or grind it just yet.

Just with clean up it only had about .001" runout on the body & .0002" rounout on the face, +/- .0001" depending on where I measure it. Didn't see a need to face it at this time.

It came with the original key (square rather than hex like most others) but I wanted one with a bit longer handle. 7mm square keys are hard to find so I thought for sure I would have to make one. Found one from Myford, even coming from the UK it was a good price & good quality. Handle was way too long so I shortened it.

First thing I made. I needed a spacer for my slitting saw arbor. Wanted it as flat as possible so it wouldn't add any runout which was a success.

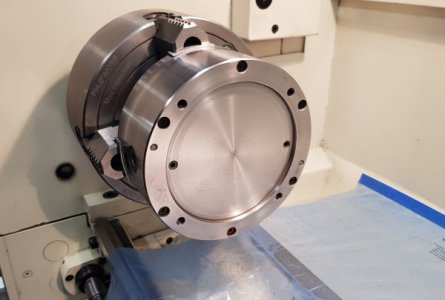

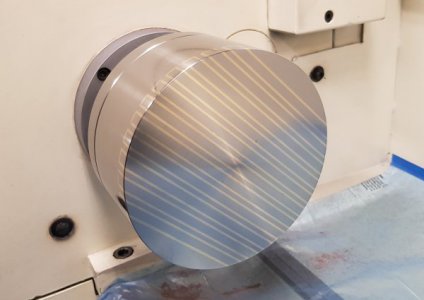

I didn't know what to expect spinning an 8" dia x 3/4" thick piece of cast iron even though it was only going to be a skim cut. I yanked on it pretty hard & couldn't budge it. Still, I used two MT extensions as a safety catch (don't mind the annular cutter arbor, tried that before adding the second extension & just left it in). Even it if it knocked loose I'm sure it wouldn't have completely seperated but better safe than sorry.

I didn't know what to expect spinning an 8" dia x 3/4" thick piece of cast iron even though it was only going to be a skim cut. I yanked on it pretty hard & couldn't budge it. Still, I used two MT extensions as a safety catch (don't mind the annular cutter arbor, tried that before adding the second extension & just left it in). Even it if it knocked loose I'm sure it wouldn't have completely seperated but better safe than sorry.

I figure there are more worst ways to waste my money .

I figure there are more worst ways to waste my money .