- Joined

- Mar 22, 2014

- Messages

- 870

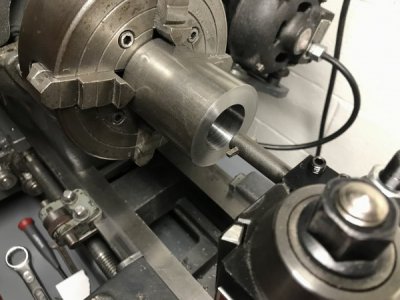

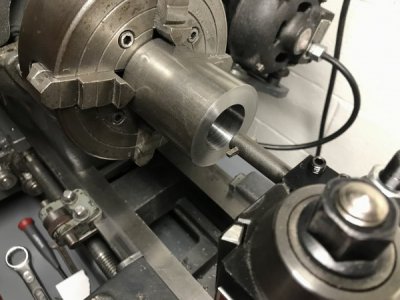

Just completed an ER40 collet chuck for my Craftsman (Atlas) 12-inch lathe. I followed the excellent drawing by Ronald Crowell, Harold Hall's website, and the many YouTube tutorials. This was a real nice learning experience with a variety of operations... boring a precise diameter, internal thread relief, internal threading, external metric threading, boring a taper, and the order of operations was important. I'm getting a TIR of about 0.0005 on a .500 pin gauge. I think this is okay, considering that I am using an economy collet and chuck, and I'm nowhere near the proper nut torque. The repeatability of installation on the spindle is good - that is, I can measure TIR, take the collet off the spindle, put it back on and get very close to the same TIR.