- Joined

- Feb 8, 2014

- Messages

- 11,176

Yesterday I was looking for a reamer in a box and found a 1/4 inch solid carbide spotting drill in the bottom. So I put the drill in my countersink rack.

Today I broke a 5/16-18 tap about 5/8 deep in a part, a brand new OSG spiral flute. This of course was the last operation on a matched pair of parts. So first try the normal stuff to get the tap out, needle nose pliers, tapping on it with one of my broken bolt removing punches. Nope, it was stuck tight. OK, probe around a bit with a carbide scribe to remove any loose pieces on top, and blow out with the air hose. Then try a carbide cone burr to see if I could plunge into it. I got a little way, at least I had a good center divot. Then I tried a 1/4 ball carbide burr, it only went down a little ways but did give me a nice wide starter center for something.

So first try the normal stuff to get the tap out, needle nose pliers, tapping on it with one of my broken bolt removing punches. Nope, it was stuck tight. OK, probe around a bit with a carbide scribe to remove any loose pieces on top, and blow out with the air hose. Then try a carbide cone burr to see if I could plunge into it. I got a little way, at least I had a good center divot. Then I tried a 1/4 ball carbide burr, it only went down a little ways but did give me a nice wide starter center for something.

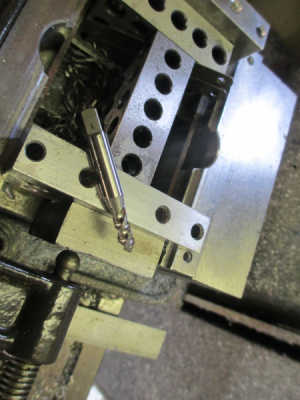

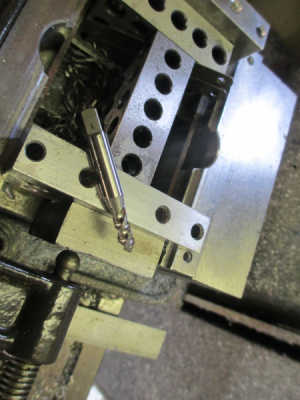

Then I thought of the spotting drill, chucked it up, and started chewing on the tap. About 500 RPM, a lot of pressure, and mist coolant. It was going through it fast enough that I thought the drill was being pushed up into the chuck, but I actually managed to DRILL the tap out with the spotting drill. This would not have worked had I not prepped the operation with the carbide burrs to give the drill a good center to start in, the drill bit would have just walked sideways and shattered.

This tap used to be about 5/8 longer

This is what the tap used to look like. I like these for blind holes, they pull the chips up rather than packing them into the bottom of the hole.

One drill flute came out fine

Chipped the other flute a bit when the tap broke up in the hole and caught the lip.

Today I broke a 5/16-18 tap about 5/8 deep in a part, a brand new OSG spiral flute. This of course was the last operation on a matched pair of parts.

Then I thought of the spotting drill, chucked it up, and started chewing on the tap. About 500 RPM, a lot of pressure, and mist coolant. It was going through it fast enough that I thought the drill was being pushed up into the chuck, but I actually managed to DRILL the tap out with the spotting drill. This would not have worked had I not prepped the operation with the carbide burrs to give the drill a good center to start in, the drill bit would have just walked sideways and shattered.

This tap used to be about 5/8 longer

This is what the tap used to look like. I like these for blind holes, they pull the chips up rather than packing them into the bottom of the hole.

One drill flute came out fine

Chipped the other flute a bit when the tap broke up in the hole and caught the lip.