I'm a newbie that recently added CNC capability to an old LC30A mill using Mach3. I have next to no experience other than typing in some simple G0, G1 etc. commands and cutting a few arcs using the Wizard feature. I'm not a machinist, just a guy that likes to tinker.

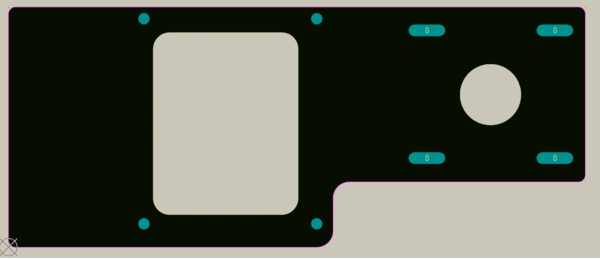

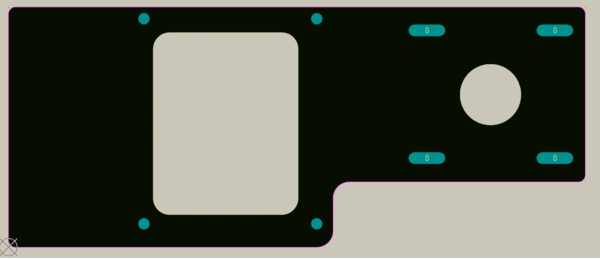

I now want to attempt machining a fairly simple irregular shaped piece. To start, I just want to cut the perimeter that would be a sequence of straight cuts and 6 arcs. I imagine the mill going around the perimeter several times cutting a bit deeper on each pass until the bit finally cuts through the bottom edge. I suppose I can run the arc wizard 6 times and copy the 6 code segments it generates to a new file and then insert the straight line cuts (G01) in the appropriate locations in the new file, so that the entire perimeter is defined.

Is there a better approach, perhaps with some form of (low cost or free) cad software, or is the method I described above a reasonable approach?

Thanks to all that reply.

I now want to attempt machining a fairly simple irregular shaped piece. To start, I just want to cut the perimeter that would be a sequence of straight cuts and 6 arcs. I imagine the mill going around the perimeter several times cutting a bit deeper on each pass until the bit finally cuts through the bottom edge. I suppose I can run the arc wizard 6 times and copy the 6 code segments it generates to a new file and then insert the straight line cuts (G01) in the appropriate locations in the new file, so that the entire perimeter is defined.

Is there a better approach, perhaps with some form of (low cost or free) cad software, or is the method I described above a reasonable approach?

Thanks to all that reply.