I have a Jet 9x20 belt driven lathe that I am trying to use. It is actually my dad's lathe and was bought used. He had used the carriage lock to take up the play in the carriage. It moves up and down quite a bit with the lock backed off. I took the carriage off the machine and cleaned it up and relubed it. I noticed the two bars that slide on the bottom of the ways are worn a lot.

This is the plate from the back of the carriage. I saw where someone made their own brass plates and I read another thread where someone made angled plates. It appears that the plate only needs to be flat and the wear has caused the raw/silver portion to become stepped (lower) than the side that has the mounting holes.

This lathe is pretty much useless with this much slop.

How should I go about fixing this?

Flip the plates over?

Machine the entire surface flat again on my import bench top mill?

Make or buy brass in the same thickness?

Buy new replacement parts, if they are even available?

Today, I cleaned up the surfaces on the mill with some 0000 steel wool and oil. The ways were nasty and had some rust as well as the carriage and cross slide, and the 8" chuck must not have been oiled so it started to rust with the rain we finally had. I assume the steel wool won't hurt any of the surfaces as the ways are hardened and I read of others using steel wool and oil to clean light rust. It also seems safe for blued gun parts. It did a good job cleaning up the steel, but it isn't new looking. I tried to clean up the bits of steel wool and keep it out of any moving parts. Maybe I will try scotch bright pads next time.

The ways have a few dings on top, but they don't appear worn to the naked eye. I have not put a rule on them yet. I read on this forum that scraping the ways can be quite costly. Hopefully, they are good and only the plates wore.

My dad has always wanted a QCTP for this machine. Now that I have used the machine, I see the use for one. I was thinking of the AXA 100 import set from https://littlemachineshop.com/products/product_view.php?ProductID=2280&category=-419988835 and a mounting adapter stud, and a 4 bolt plate for the compound slide.

Does anyone have input on this QCTP setup for a 9x20 lathe? I think my dad would like the larger steel version over the small aluminum versions that are made for this lathe. I would get the kit with the tool holders.

My brother bought a USA made set of indexable tool holders. They are Rutland tool and supply part number 20358000. The part number comes up on MSC as a $200 set: http://www.mscdirect.com/product/de...&pxno=29536509&refnum=29536509&rItem=78641081

If it is the same set (looks like it), then the inserts are: TT 321

Will these inserts work? https://littlemachineshop.com/products/product_view.php?ProductID=3698&category=-1550042347

The holders are 1/2" square stock and the edge of one side of the triangular cutter is just over half an inch. They are carbide and only one seemed to cut well on the aluminum project I did, which was turning a 1 5/8" piece of 6061. The best finish was when I took a couple thousandths off at a spindle speed of 1,000 rpm. The machine is too unstable to take more than 20 thousandths at a time at 600 rpm. I got some chatter and an ugly finish, but I was just roughing. I did the final few passes at the higher speed.

I understand that HSS is better for hobby work, so I would like to get HSS inserts. The few HSS bars we have are bent (don't know the history of them). I could learn to grind my own, but I really like the indexable set that we have.

We use a good amount of aluminum in our projects and also steel. We use stainless and brass on occasion.

The other items we don't have is a good borring bar and center drills. For the borring bar, I was thinking it would be nice if it used the same triangular insert. We don't have anything for threading either and I am not sure if we need a special tool or one of the tools we already have.

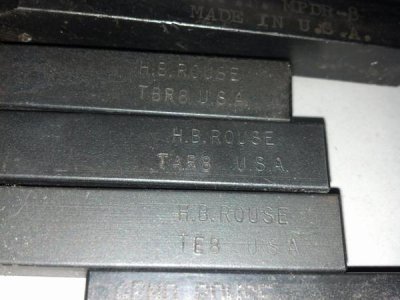

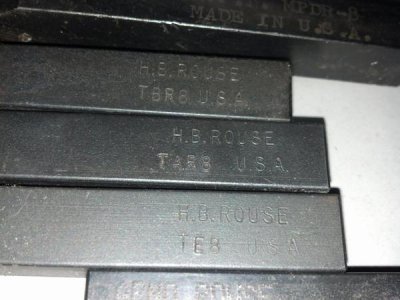

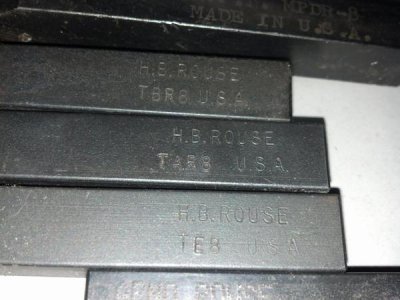

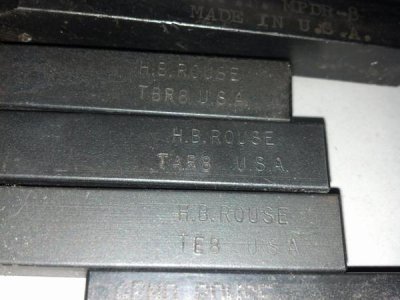

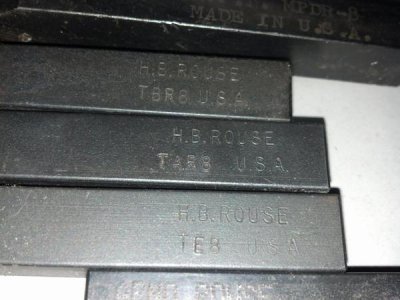

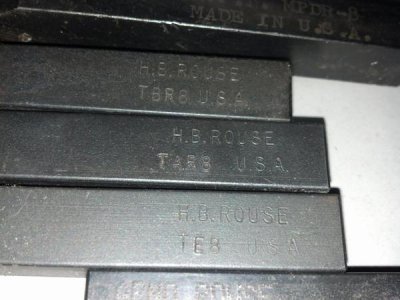

Here is a pic of the tool set we do have:

I have no idea what the tool on the left is, I don't remember if it has any stamping and I have not used it. The inserts are obviously different. It may be one that my dad or brother bought from a used tool supplier we used to go to. Unfortunately it isn't run the same as it used to be. In the past we could buy misc. milling tools by the pound.

Any guidance you could give me would be great. Thanks, Chris.

This is the plate from the back of the carriage. I saw where someone made their own brass plates and I read another thread where someone made angled plates. It appears that the plate only needs to be flat and the wear has caused the raw/silver portion to become stepped (lower) than the side that has the mounting holes.

This lathe is pretty much useless with this much slop.

How should I go about fixing this?

Flip the plates over?

Machine the entire surface flat again on my import bench top mill?

Make or buy brass in the same thickness?

Buy new replacement parts, if they are even available?

Today, I cleaned up the surfaces on the mill with some 0000 steel wool and oil. The ways were nasty and had some rust as well as the carriage and cross slide, and the 8" chuck must not have been oiled so it started to rust with the rain we finally had. I assume the steel wool won't hurt any of the surfaces as the ways are hardened and I read of others using steel wool and oil to clean light rust. It also seems safe for blued gun parts. It did a good job cleaning up the steel, but it isn't new looking. I tried to clean up the bits of steel wool and keep it out of any moving parts. Maybe I will try scotch bright pads next time.

The ways have a few dings on top, but they don't appear worn to the naked eye. I have not put a rule on them yet. I read on this forum that scraping the ways can be quite costly. Hopefully, they are good and only the plates wore.

My dad has always wanted a QCTP for this machine. Now that I have used the machine, I see the use for one. I was thinking of the AXA 100 import set from https://littlemachineshop.com/products/product_view.php?ProductID=2280&category=-419988835 and a mounting adapter stud, and a 4 bolt plate for the compound slide.

Does anyone have input on this QCTP setup for a 9x20 lathe? I think my dad would like the larger steel version over the small aluminum versions that are made for this lathe. I would get the kit with the tool holders.

My brother bought a USA made set of indexable tool holders. They are Rutland tool and supply part number 20358000. The part number comes up on MSC as a $200 set: http://www.mscdirect.com/product/de...&pxno=29536509&refnum=29536509&rItem=78641081

If it is the same set (looks like it), then the inserts are: TT 321

Will these inserts work? https://littlemachineshop.com/products/product_view.php?ProductID=3698&category=-1550042347

The holders are 1/2" square stock and the edge of one side of the triangular cutter is just over half an inch. They are carbide and only one seemed to cut well on the aluminum project I did, which was turning a 1 5/8" piece of 6061. The best finish was when I took a couple thousandths off at a spindle speed of 1,000 rpm. The machine is too unstable to take more than 20 thousandths at a time at 600 rpm. I got some chatter and an ugly finish, but I was just roughing. I did the final few passes at the higher speed.

I understand that HSS is better for hobby work, so I would like to get HSS inserts. The few HSS bars we have are bent (don't know the history of them). I could learn to grind my own, but I really like the indexable set that we have.

We use a good amount of aluminum in our projects and also steel. We use stainless and brass on occasion.

The other items we don't have is a good borring bar and center drills. For the borring bar, I was thinking it would be nice if it used the same triangular insert. We don't have anything for threading either and I am not sure if we need a special tool or one of the tools we already have.

Here is a pic of the tool set we do have:

I have no idea what the tool on the left is, I don't remember if it has any stamping and I have not used it. The inserts are obviously different. It may be one that my dad or brother bought from a used tool supplier we used to go to. Unfortunately it isn't run the same as it used to be. In the past we could buy misc. milling tools by the pound.

Any guidance you could give me would be great. Thanks, Chris.