- Joined

- Oct 4, 2011

- Messages

- 727

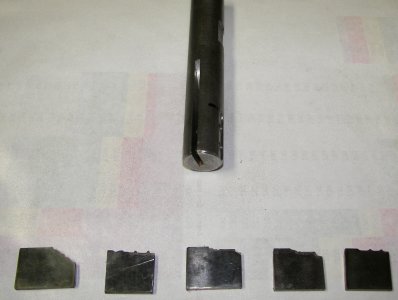

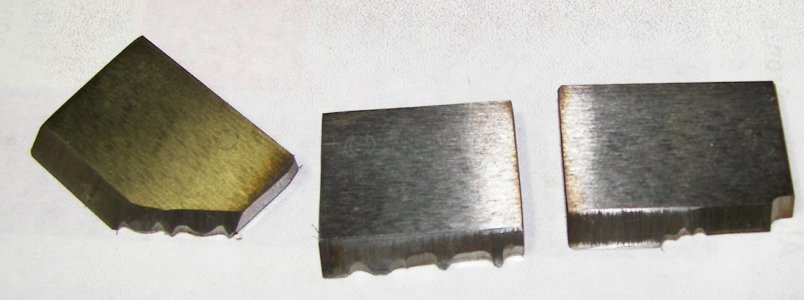

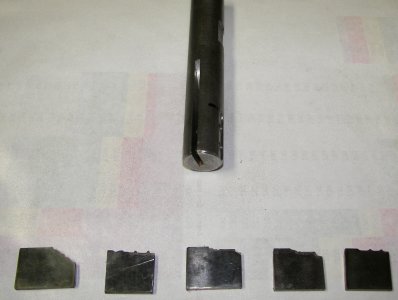

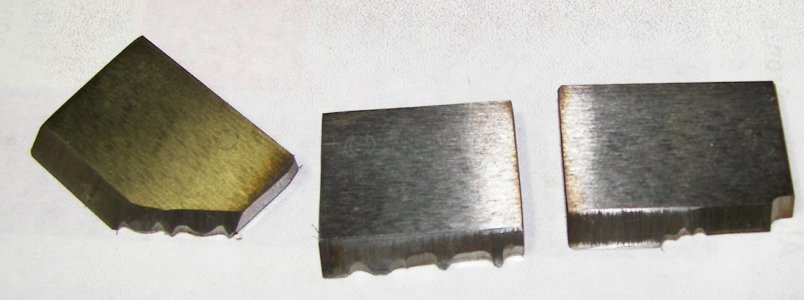

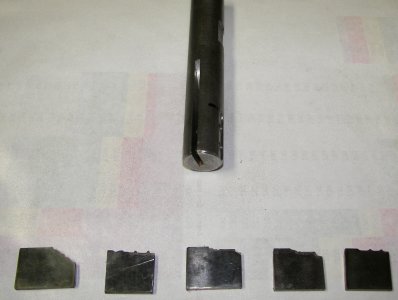

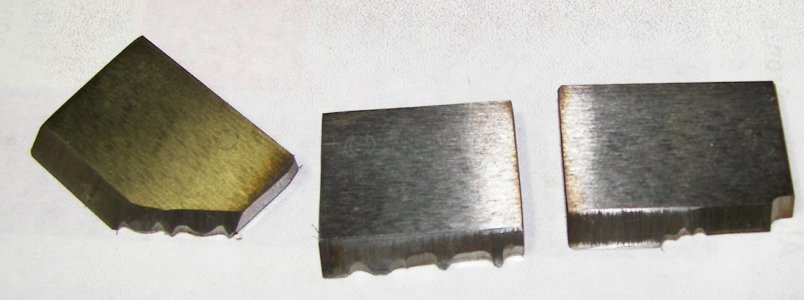

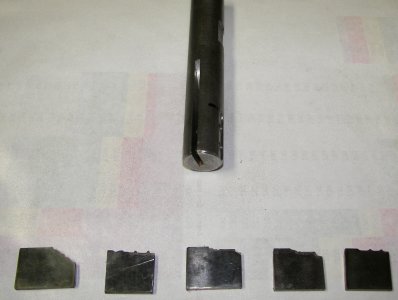

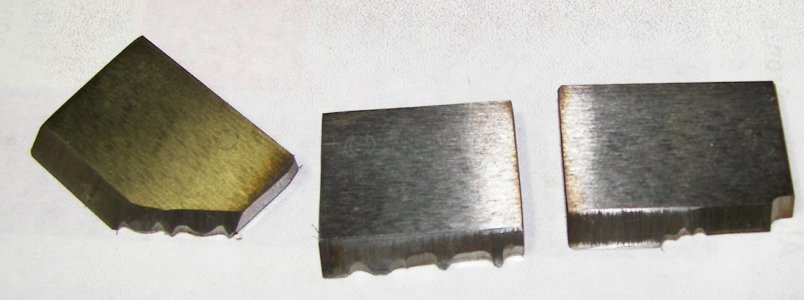

I am building a dollhouse for my niece and needed to make some custom molding. I made a single point cutter from a piece of .750" 1018. The cutting bit is made from sections of old planer blades. Since there is only one cutter I don't have to worry about matching cuts.

A simple jig on the mill to hold the stock. I cut at the highest RPMs on the mill and use the power feed. Using a climb mill cut the molding comes out smooth as silk. No sanding required.

This setup gives me 14" pieces. This cutter works great on wood and plastics. Have not needed to try it on metals yet.

This is a room with the trim.

Jeff

A simple jig on the mill to hold the stock. I cut at the highest RPMs on the mill and use the power feed. Using a climb mill cut the molding comes out smooth as silk. No sanding required.

This setup gives me 14" pieces. This cutter works great on wood and plastics. Have not needed to try it on metals yet.

This is a room with the trim.

Jeff