- Joined

- Feb 8, 2014

- Messages

- 11,176

This comes up often, so I'll post what I did. It was a quick job, not pretty but it works. Not much to this project, maybe took a half day to complete.

I picked this saw up at auction for $25, it needed a little love to in addition to the conversion. I had to build a new lower blade guide assembly, and repair the keyway in the main wheel drive shaft.

In this case I just used parts I had on the shelf rather than buying anything. Not ideal but it has been working for years. Cuts anything from tool steel to wood. I do buy good bi-metal M42 cobalt blades fo it, have a local vendor make them up for me.

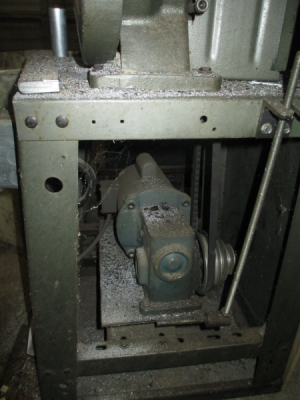

I replaced the original 3/4 hp motor with a 1/2 hp, 2 speed motor and 30:1 right angle gearbox, a 15:1 gearbox might be a better choice. The rod on right is the belt tensioner, I had a spring on it, but it turned out to be more trouble than it was worth.

Must have a spider living in there, a few cobwebs in the corner

The motor mount plate is hinged with a couple of heavy cabinet hinges, allows the motor assembly to swing to easily do speed changes.

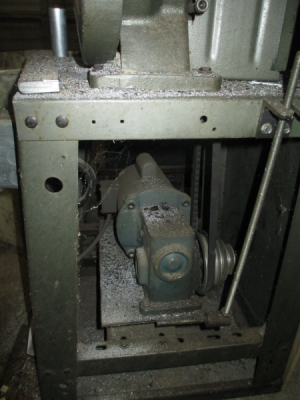

The motor belt drives this original countershaft assembly. I may have purchased the wheel drive pulley, I think the keyway was completely gone in the original as I recall.

1 1/4 thick 4150

If I ever break this one maybe I'll get a DoAll

I picked this saw up at auction for $25, it needed a little love to in addition to the conversion. I had to build a new lower blade guide assembly, and repair the keyway in the main wheel drive shaft.

In this case I just used parts I had on the shelf rather than buying anything. Not ideal but it has been working for years. Cuts anything from tool steel to wood. I do buy good bi-metal M42 cobalt blades fo it, have a local vendor make them up for me.

I replaced the original 3/4 hp motor with a 1/2 hp, 2 speed motor and 30:1 right angle gearbox, a 15:1 gearbox might be a better choice. The rod on right is the belt tensioner, I had a spring on it, but it turned out to be more trouble than it was worth.

Must have a spider living in there, a few cobwebs in the corner

The motor mount plate is hinged with a couple of heavy cabinet hinges, allows the motor assembly to swing to easily do speed changes.

The motor belt drives this original countershaft assembly. I may have purchased the wheel drive pulley, I think the keyway was completely gone in the original as I recall.

1 1/4 thick 4150

If I ever break this one maybe I'll get a DoAll

Last edited: