A motor will self generate power as it slows down and there is some charge in the capacitor bank that can keep the VFD powered for minutes after the power is disconnected. They also indicate to wait at least 5 minutes after turning off a VFD and checking the voltages before handling any of the connections. There is also the added factor that frequent switching on-off-on of the VFD can damage/destroy the inrush circuitry, and I have seen this happen on several VFD's.

It is not advised to shut down the VFD while the motor is running, and it will also slow the braking time. An E-Stop at the machine is typically designed to shut down the machine/movement as fast as possible and then prevent the potential for restart. Also in some cases it is also designed to prevent the output section of the VFD operating even on power up (STO). One always needs to have some level of redundancy, as well as hierarchical programmed inputs on the assumption that a run or stop switch fails. How this is implemented is based on the VFD, programmable inputs and control system operations, whether this be solid state, relay or other type of controller system.

My approach has been to typically have 3 levels of interlocks and controls for an E-Stop, the first is at the relay level that issues the commands has a power latching relay that drops out for any fault/E-Stop, this prevents the other relays from operating and also interrupts the VFD run signal. The E-Stop is mechanical redundant switch which stops power to the control system, also interrupts the VFD control circuit and turns on a VFD input programmed as an E-Stop (on some VFDs). The programmed E-Stop input is set for the fastest braking, and also supersede any other active run command and often requires a VFD reset as well as the run command can not be active. Other stop systems also have a similar redundancy. If one wanted to take this to the next level you could add a STO circuit once the VFD had a 0 speed output detected using one of the relay programmed outputs.

I recently had the experience where an individual with a lathe (1340) used the STO function for the E-Stop and then was mentioned that the chuck kept spinning for a long time after he pressed the E-Stop, the STO circuit prevents the VFD output section from operating and therefore there has no VFD braking. He rewired it back the way I indicated.

As far as powering the VFD, most of us do not use our machines on a regular bases, so leaving the VFD on all the time is not warranted (exception may be very cold climates which can damage the capacitors). I usually recommend if you are going to be using a VFD powered machine through the day, then turn it on when you start the day, and turn it off at the end of the day. This is also a safety precautions if someone else had access to your shop/garage or you have little ones running around. Frequent powering on/off cycling of a VFD will cause it to fail sooner, using a contactor to tun on/off a VFD is OK, and but not as a safety E-Stop in my view. Almost all VFD's have programable features which prevent a VFD restart with an active run command on power-up.

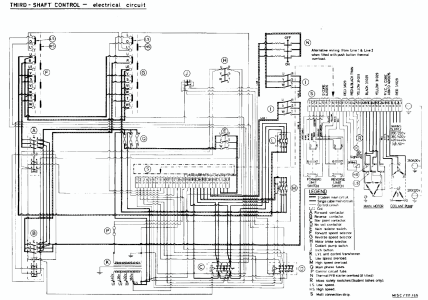

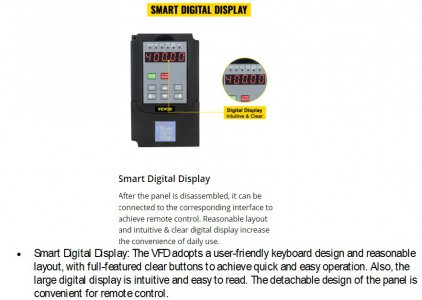

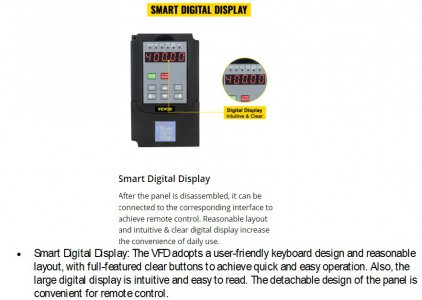

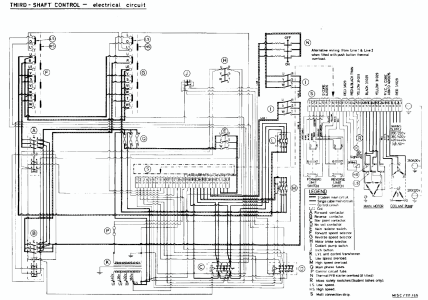

To get back the lathe at hand, my understanding that the application being considered for this is a Colchester Triumph Mk 1/2 round head lathe that is setup for 575V. I have looked at similar lathe models and the do not use a simple spindle switch setup/control system, so adapting to a VFD control system would be more challenging and in most cases, a complete replacemnt control system, and the Vevor A2 series does not support most of the common programming and control options discussed. My advice would be to see if the lathe can be rewired for 240VAC 3 phase, repalce the motor with a 230VAC 3 phase model, all of which woul also require changing the fuses/heaters, and then powering it with a Phase Perfect or RPC if you wanted to keep the functionality of the current controls. Would need to know more about its operation, but I think one would be beter off doing a complete replacement VFD control system for full functionality. If your lathe uses a clutch drive system and has electro mechanical brake system already built into the lathe then it is a bit differnt.