- Joined

- Oct 13, 2014

- Messages

- 9,687

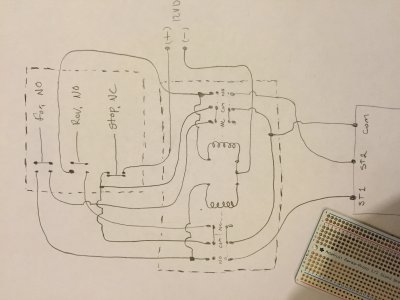

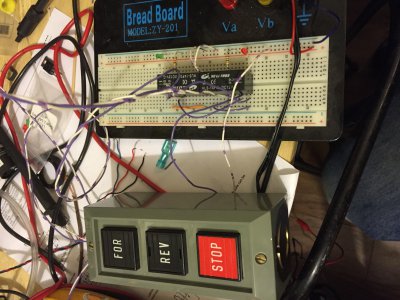

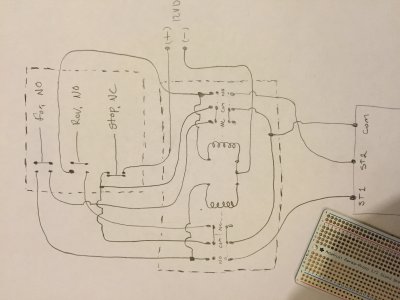

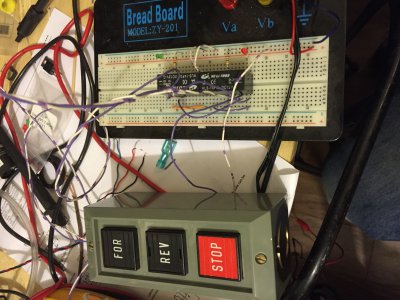

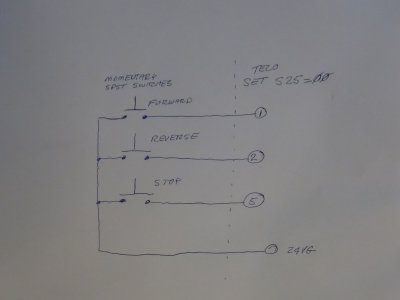

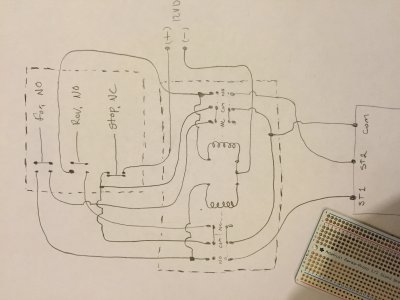

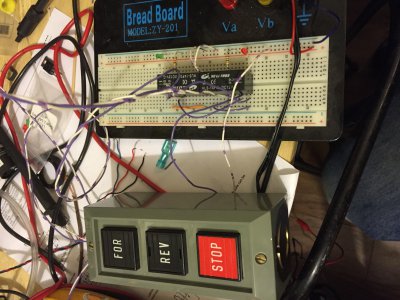

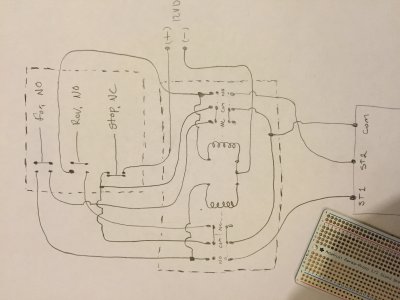

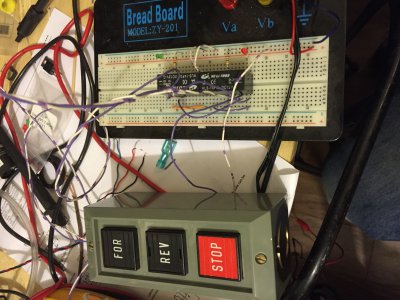

I just installed a Teco L510 VFD to run my mill. I wanted to use a momentary pushbutton "Forward", "Reverse" and "Stop" switch, However, the VFD requires the switch status to be constant, so I designed a simple circuit using two latching DPDT relays to achieve the correct interface. I also made it so the latched relay will shunt the other relay, thus preventing the switch status from being in "run forward" and "run reverse" simultaneously. The VFD does have protection against that condition, but I figured it easy enough to do and it allows me to possibly attach other things to the circuit such as indicator lights etc.

I will be adding other features in the near future. One I am considering is a switch on the Hi/Lo Shift lever that would swap the forward and reverse relays so the directional pushbuttons will always be correct.

I attached photos/video of the schematic (please excuse the sloppy drawing) breadboard testing, final build and installation.

I will be adding other features in the near future. One I am considering is a switch on the Hi/Lo Shift lever that would swap the forward and reverse relays so the directional pushbuttons will always be correct.

I attached photos/video of the schematic (please excuse the sloppy drawing) breadboard testing, final build and installation.