- Joined

- Oct 29, 2012

- Messages

- 1,387

I've been "about to" get into metal casting for a few years now, and my level of interest is finally about to surpass my tendency to procrastinate.

I want to cast iron. I will start with aluminum as it seems an obligatory entry point into the craft but I don't want to invest in a technology that isn't suitable for casting iron because I know I'll outgrow it almost immediately.

Propane burners seem to be 80-90% of what everyone uses but as far as I can tell it's not the way to go for casting iron (possible but far from ideal). For that it seems you are better off with induction. But induction is expensive to buy or complicated to DIY.

What seems a lot less expensive and complicated is dumping a motherload of amps through a 10,000 degree arc into a crucible. But I can't find hardly any examples of anyone doing it at large-ish home/hobby scale. I find plenty of examples of the industrial scale 1.21 gigawatt smelting scene and I find plenty of shameless copies of this video by King of Random where he zapped a couple of ounces of metal between two carbon electrodes inside a tiny fire brick, but nothing in between. Why? Why is almost nobody pursuing this? It seems to me like the ideal way to melt metal. Electricity is way cheaper than propane, gets way hotter, melts way faster, and with much less rigmarole to set up the furnace and start melting. There must be some kind of fly in the ointment that I have not yet identified; what is it?

I did some tests today just using my TIG welder. Filled up a 2-1/4" socket and a sprocket bore with molten aluminum and it seems promising but I discovered that 3/32" tungsten electrodes just aren't going to cut it. I burned through 2 brand new electrodes in just a couple of minutes and also melted a TIG torch . I just ordered a length of 1/4" tungsten rod for further experimentation (and a new torch).

. I just ordered a length of 1/4" tungsten rod for further experimentation (and a new torch).

Obviously terrible result here but this is step 0 of what I'm sure will be journey.

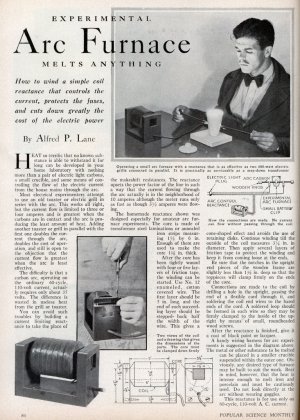

This is the only thing I have found that is even close to what I am envisioning. (And it seems like a project that was never seen through to completion)

And this (which was inspired by above):

I want to cast iron. I will start with aluminum as it seems an obligatory entry point into the craft but I don't want to invest in a technology that isn't suitable for casting iron because I know I'll outgrow it almost immediately.

Propane burners seem to be 80-90% of what everyone uses but as far as I can tell it's not the way to go for casting iron (possible but far from ideal). For that it seems you are better off with induction. But induction is expensive to buy or complicated to DIY.

What seems a lot less expensive and complicated is dumping a motherload of amps through a 10,000 degree arc into a crucible. But I can't find hardly any examples of anyone doing it at large-ish home/hobby scale. I find plenty of examples of the industrial scale 1.21 gigawatt smelting scene and I find plenty of shameless copies of this video by King of Random where he zapped a couple of ounces of metal between two carbon electrodes inside a tiny fire brick, but nothing in between. Why? Why is almost nobody pursuing this? It seems to me like the ideal way to melt metal. Electricity is way cheaper than propane, gets way hotter, melts way faster, and with much less rigmarole to set up the furnace and start melting. There must be some kind of fly in the ointment that I have not yet identified; what is it?

I did some tests today just using my TIG welder. Filled up a 2-1/4" socket and a sprocket bore with molten aluminum and it seems promising but I discovered that 3/32" tungsten electrodes just aren't going to cut it. I burned through 2 brand new electrodes in just a couple of minutes and also melted a TIG torch

Obviously terrible result here but this is step 0 of what I'm sure will be journey.

This is the only thing I have found that is even close to what I am envisioning. (And it seems like a project that was never seen through to completion)

And this (which was inspired by above):

been there, fried that, bought it... suddenly 1/4" Aluminum is weldable!

been there, fried that, bought it... suddenly 1/4" Aluminum is weldable!