Well, got the arbor out. I ended up cutting it off nearly flush to the chuck, drilling most of the rest out and I had to make a 7/16 hole in the chuck itself to get a big enough punch on the back side of the arbor.

Even then, it did not want to come out. Heat, cold, etc…just would not move. I even had it pressed in the large bench vice at one point, crushed with a 3 foot cheater bar and the vice locked up so solid it wouldn’t go any further. Tried heat and cold again with it under vice pressure, no go.

I finally ended up on the floor on top of a steel anvil with a fabricated punch (sized exactly to the 7/16 hole to give it as much strength as possible, anything smaller would just bend) and beating on the punch with a 5 lb sledge. I figured no way after the vice refusal, but it finally let go after 5-10 hits. Once apart, I could see a very thin coating of rust on the taper and chuck bore, so the arbor and chuck had likely almost “welded” themselves together.

I already had the chuck apart again to do the abusing work, so I chucked the main body up in the lathe and shaved a thou or two off the exterior surfaces. None of the critical dimensions were touched, except skimming about 2 thou off the face where the jaws come out. Cleaned up all the decades of abuse and hammer dings. Not all of them, but most so it just looks like a regular used chuck. The gear ring was in decent shape, so I didn’t touch that other than a degreasing and cleaning.

While it was apart, all of it got a good scrubbing and drying. I also stoned a few more things internally and gave it a good coat of white lithium grease. Movement is now buttery smooth.

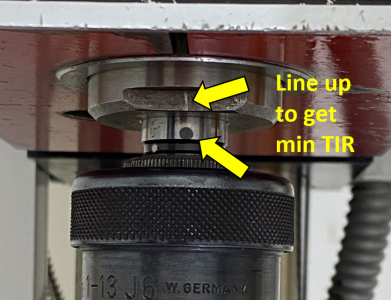

Dropped a new JT3 arbor in the chuck and after a little massaging, got a TIR of 0.0045 with a 5/8 end mill chucked up to give a running surface for the dial indicator. Thats 0.0045 TIR about 1.5 inches away from the tip of the jaws. I’ll call that “acceptable”, especially for a drill press Where the runout is about 4 thou to start with.

Heres a couple pics of the finished product:

When I get a few spare minutes, I’ll probably grab some “Neverdull” and give it a good final polish/buffing.

The jaws are “ok”, but they do show some wear internally.

I’ll be keeping my eye out for a NOS rebuild kit and I’m also going to have to order the correct chuck key, but not bad for 25 bucks and a couple days work….