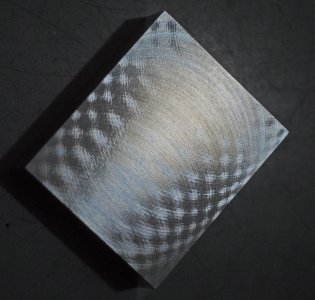

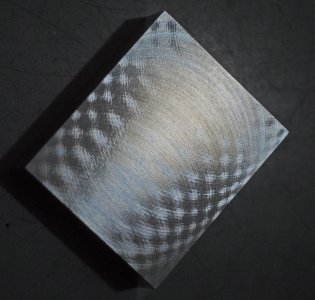

It's a hobby-grade EMCO FB-2 milling machine fitted with a 40mm diameter face milling head, 4 blades. Material is 7075 Aluminium alloy, cutting depth 0.1 mm ( finishing ) RPM 680, feeding speed 65 mm / 2.56 inch per min. All the inserts are very new. When I used them for the first time, there was no such checker board marks. What could have changed to cause this ? That said, these marks are no issue at all and I could not feel it with my fingers but I would like to know whether they are indicating the onset of any problems.

Last edited: