Minions

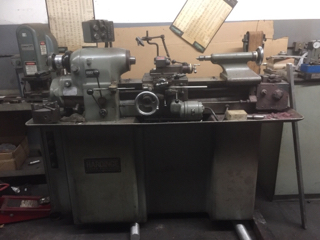

I purchase a non-running HLV-H #6815-P (1977) in April 2016. This is a SHORT list of things I learned and fixed. Some were very easy, others required lots of study and research.

What is the serial Number#? Note: all three should match 1)tail stock-underneath cam lock 2)End of the bed backside top of taper rail 3) Head stock above collet closer mounting holes on the top. I did not know this until after the purchase, Mine all matched.

Also get a picture of the Data plate on the control cabinet. This will give you the supply voltage needed. Mine is 230 volts 3 phase supply needed. (to size your Rotary Phase Converter)

A picture of the inside of the control cabinet, will help give clues - If you see smoke staining or drips of black /brown tar below the step down control transformer, it is burnt out! (I purchased a Cutter Hammer 230v input to 115v output off ebay $60) The local parts house wanted $350

The fuse on the 115volt side of the transformer was blowen - Not allowing current to the power feed. Replacements on ebay $10 I purchased a lot of 5, blew 3 fuses during trouble shooting. (learning curve)

Spindle lock was broken. Machined a new one on my mini lathe. Checked the spindle lock electrical interrupter switch -(location behind Hardinge plate on the front.) Mine was in the open position due to the broken spindle lock, not allowing electrical current to the machine on/off switch.

on/off switch, pilot light will not work. switch transformer burnt out. Currently working on finding replacement.

Cooling pump and lines completely packed tight with metal crud. Disassembled and cleaned.

Burnt out power feed module - Replaced with new 2016 circuit board. $60

Wires from the Master fuse block connected by one wire strand and loose. Easy fix

Removed "Custom Wiring and external 120volt outlet" from one leg of the 3 phase circuit.

Brake was completely seized up. Fixed- Disassembled and cleaned works great now.

Tail Stock off center .004" The quill lock lever nut frozen in place pulling quill to one side.

Tail Stock gib had a .005" dish in the center. Easy fix

Oiler system on carriage completely clogged in operable. DO NOT TWIST to REMOVE! broke small copper line My fault! (Learning curve)

Recommend purchase of reprint Hardinge Maintained Manual off ebay. It really helped. Every system will have to be disassembled and cleaned. My lathe is fully usable after 6 months of work.

That lathe looks older than 1980- due to the large power feed box

I would not pay 5k,, more like $2500 because it is a Major Obsolete Project Lathe, Not under power and there are many problems with it. Because; if it ran it would be a lot more money.

Expect lots of self study and research. Even the Hardinge dealers no longer carry wire diagrams. I used basic electrical knowledge and a volt meter and continuity tester. Now that I have passed the 50% mark on the learning curve. I would do it again if I found another one at the $2500 price point. give or take a few hundred..

This lathe weight is 1700 lbs. Don't forget about The Special lifting points and rigging.per the manuals, (A Jack was used for lifting in picture, check for control cabinet door damage) and transportation home.

Respectfully

co1859