- Joined

- Feb 28, 2019

- Messages

- 530

So tonight my Sieg 2.7x HiTorque bench mill from Little Machine shop all of a sudden refused to stay on. I wasn't doing anything demanding and it just shut off. Hitting the green on button would fire it up but it would shut off as soon as you released the button. I could run it just fine as long as I kept the button pressed. So clearly something got messed up with the safety/emo feature with power fail lock out (if the power drops out for a sec, it won't just resume when power comes back - a good feature).

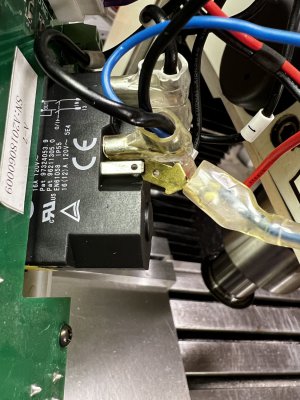

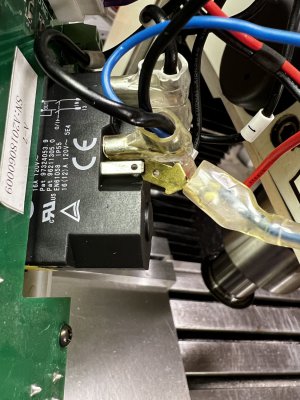

So I pulled the front control panel off and poked around and found this:

That's two male connectors at the bottom of the switch block. The blue wire with the plastic insulator shroud pulled back is supposed to connect to the lug on the switch. It's the connection that's required to keep everything on after a momentary contact of the green on button.

It was built this way! the only thing making the connection kind of work was the insulating sock and lack of space. The clear part was kind of tight enough to mostly make sure that the crimp on tab was touching the lug on the switch!!

Well, this explains why I had occasionally had unexpected shutoffs of my milll over the 3-4 years I've had it. Usually when I was pushing things and it got the shakes! Imagine that.

Fortunately I had the right type (but wrong size) mating connector kicking around and was able to limp on with it woking for the night. I need to get a smaller one and fix it properly this weekend.

All in all I've been pretty happy with this mill, and I have no beef with LMS - I'm sure if I'd contacted them they would have made it right / helped me get it debugged. However This is a pretty bad quality control issue.

So if you have a machine like this that cuts off occasionally for no good reason, you might want to open it up and take a look.

-Dave

So I pulled the front control panel off and poked around and found this:

That's two male connectors at the bottom of the switch block. The blue wire with the plastic insulator shroud pulled back is supposed to connect to the lug on the switch. It's the connection that's required to keep everything on after a momentary contact of the green on button.

It was built this way! the only thing making the connection kind of work was the insulating sock and lack of space. The clear part was kind of tight enough to mostly make sure that the crimp on tab was touching the lug on the switch!!

Well, this explains why I had occasionally had unexpected shutoffs of my milll over the 3-4 years I've had it. Usually when I was pushing things and it got the shakes! Imagine that.

Fortunately I had the right type (but wrong size) mating connector kicking around and was able to limp on with it woking for the night. I need to get a smaller one and fix it properly this weekend.

All in all I've been pretty happy with this mill, and I have no beef with LMS - I'm sure if I'd contacted them they would have made it right / helped me get it debugged. However This is a pretty bad quality control issue.

So if you have a machine like this that cuts off occasionally for no good reason, you might want to open it up and take a look.

-Dave