- Joined

- Jan 22, 2022

- Messages

- 144

To keep it simple… I’m currently a hobbyist but plan on turning my home shop into a side business and retirement job. Probably making unique small pieces (probably gun related) that I can sell.

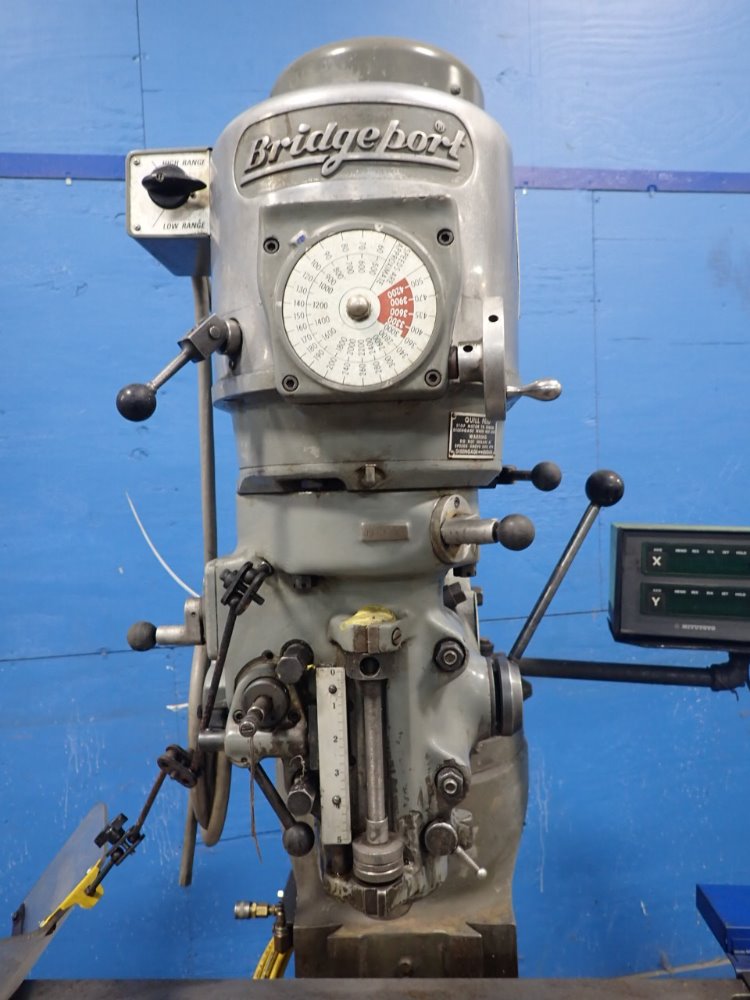

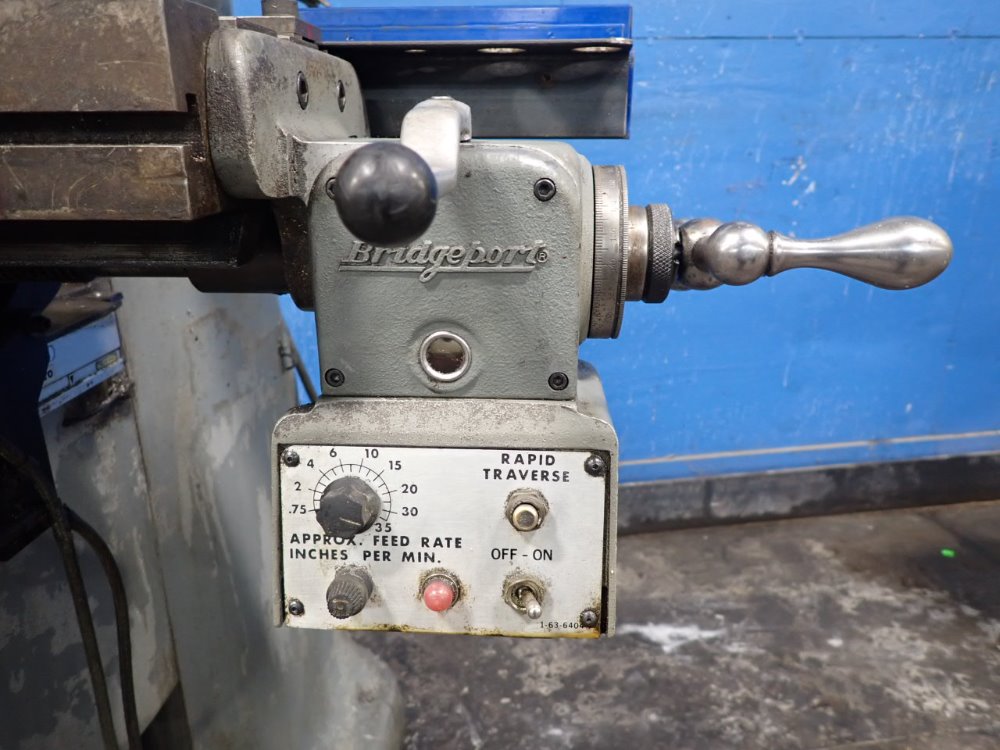

I’ve been looking for a good deal on a Bridgeport to replace my Clausing 8520. I stumbled across this Bridgeport with a 2J head on eBay from a large machine seller. It was priced at $1399. Most 2J head Bridgeports were $3000 - $4000 from the same seller. I messaged the seller and who ever replied didn’t know why it was so cheap.

I received an offer for $1000 and accepted it. I plan on picking it up this week.

I have never touched a Bridgeport!

My questions are….

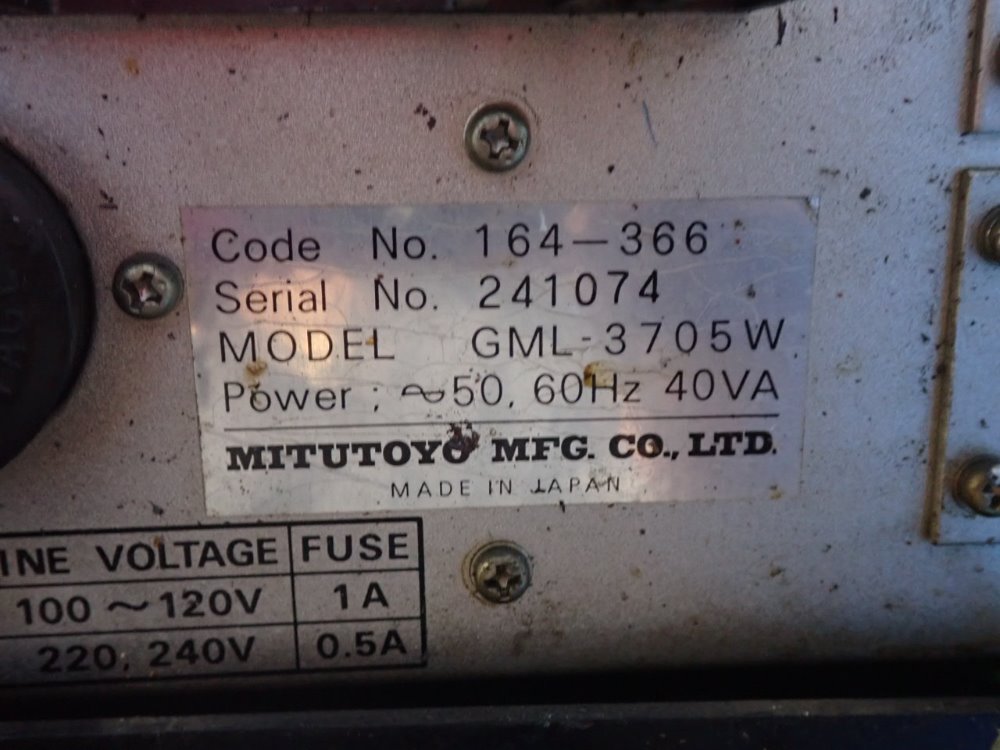

Can anyone see anything obviously wrong with it from the photos?

They have a return policy. What should I look for when I arrive to pick it up?

For this price I’m fine with a worn out bed. To a degree. I would like to attempt scraping myself.

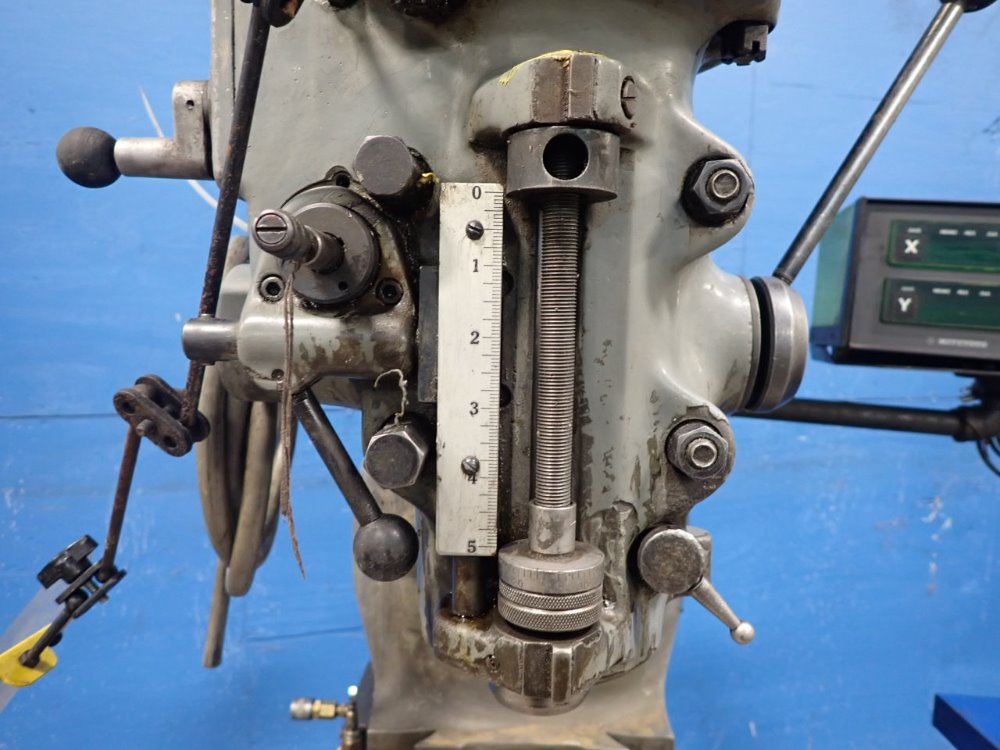

Maybe lots of spindle runout?? Can I turn it by hand and check it with an indicator?

I should buy an R8 collet and check if it fits well??

I’m assuming this is a 36” table?

Hopefully this wasn’t a big mistake! But I figured the price was worth the gamble.

I’ve been looking for a good deal on a Bridgeport to replace my Clausing 8520. I stumbled across this Bridgeport with a 2J head on eBay from a large machine seller. It was priced at $1399. Most 2J head Bridgeports were $3000 - $4000 from the same seller. I messaged the seller and who ever replied didn’t know why it was so cheap.

I received an offer for $1000 and accepted it. I plan on picking it up this week.

I have never touched a Bridgeport!

My questions are….

Can anyone see anything obviously wrong with it from the photos?

They have a return policy. What should I look for when I arrive to pick it up?

For this price I’m fine with a worn out bed. To a degree. I would like to attempt scraping myself.

Maybe lots of spindle runout?? Can I turn it by hand and check it with an indicator?

I should buy an R8 collet and check if it fits well??

I’m assuming this is a 36” table?

Hopefully this wasn’t a big mistake! But I figured the price was worth the gamble.